Metal-free batteries could make the industry more ethical and sustainable

A new scientific development is underway which could help make the battery industry more sustainable. Image: REUTERS/Joyce Zhou

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

Batteries

- Current lithium ion batteries can be ethically and environmentally problematic.

- Only a small percentage of lithium ion batteries are recycled and the cobalt needed to make them is mined using child labor in some cases.

- New research in Nature has described a new battery technology platform which involves a poypeptide organic radical construction.

- Scientists are currently working to develop this completely metal-free battery, which marks significant progress towards a sustainable and recyclable model.

A new metal-free battery platform could lead to more sustainable, recyclable batteries that degrade on demand.

The introduction of lithium-ion (Li-ion) batteries has revolutionized technology as a whole, leading to major advances in consumer goods across nearly all sectors.

While the availability of technology is generally a good thing, the rapid growth has led directly to several key ethical and environmental issues surrounding the use of Li-ion batteries.

Current Li-ion batteries use significant amounts of cobalt, which in several well-documented international cases is mined using child labor in dangerous working environments. Additionally, only a very small percentage of Li-ion batteries are recycled, increasing the demand for cobalt and other strategic elements.

New research in Nature describes a method that could lead to battery production moving away from cobalt. In the paper, researchers outline a new battery technology platform that is completely metal-free. This new battery technology platform uses a polypeptide organic radical construction.

“By moving away from lithium and working with these polypeptides, which are components of proteins, it really takes us into this realm of not only avoiding the need for mining precious metals, but opening opportunities to power wearable or implantable electronic devices and also to easily recycle the new batteries,” says Karen Wooley, professor in the chemistry department at Texas A&M University. “They [polypeptide batteries] are degradable, they are recyclable, they are non-toxic, and they are safer across the board.”

The all-polypeptide organic radical battery composed of redox-active amino-acid macromolecules also solves the problem of recyclability. The components of the new battery platform can be degraded on demand in acidic conditions to generate amino acids, other building blocks, and degradation products—one of the major breakthroughs in this research, says coauthor Jodie Lutkenhaus, professor in the chemical engineering department.

“The big problem with lithium-ion batteries right now is that they’re not recycled to the degree that we are going to need for the future electrified transportation economy,” Lutkenhaus says. “The rate of recycling lithium-ion batteries right now is in the single digits. There is valuable material in the lithium-ion battery, but it’s very difficult and energy intensive to recover.”

The development of a metal-free, all-polypeptide organic radical battery composed of redox-active amino-acid macromolecules that degrade on demand marks significant progress toward sustainable, recyclable batteries that minimize dependence on strategic metals.

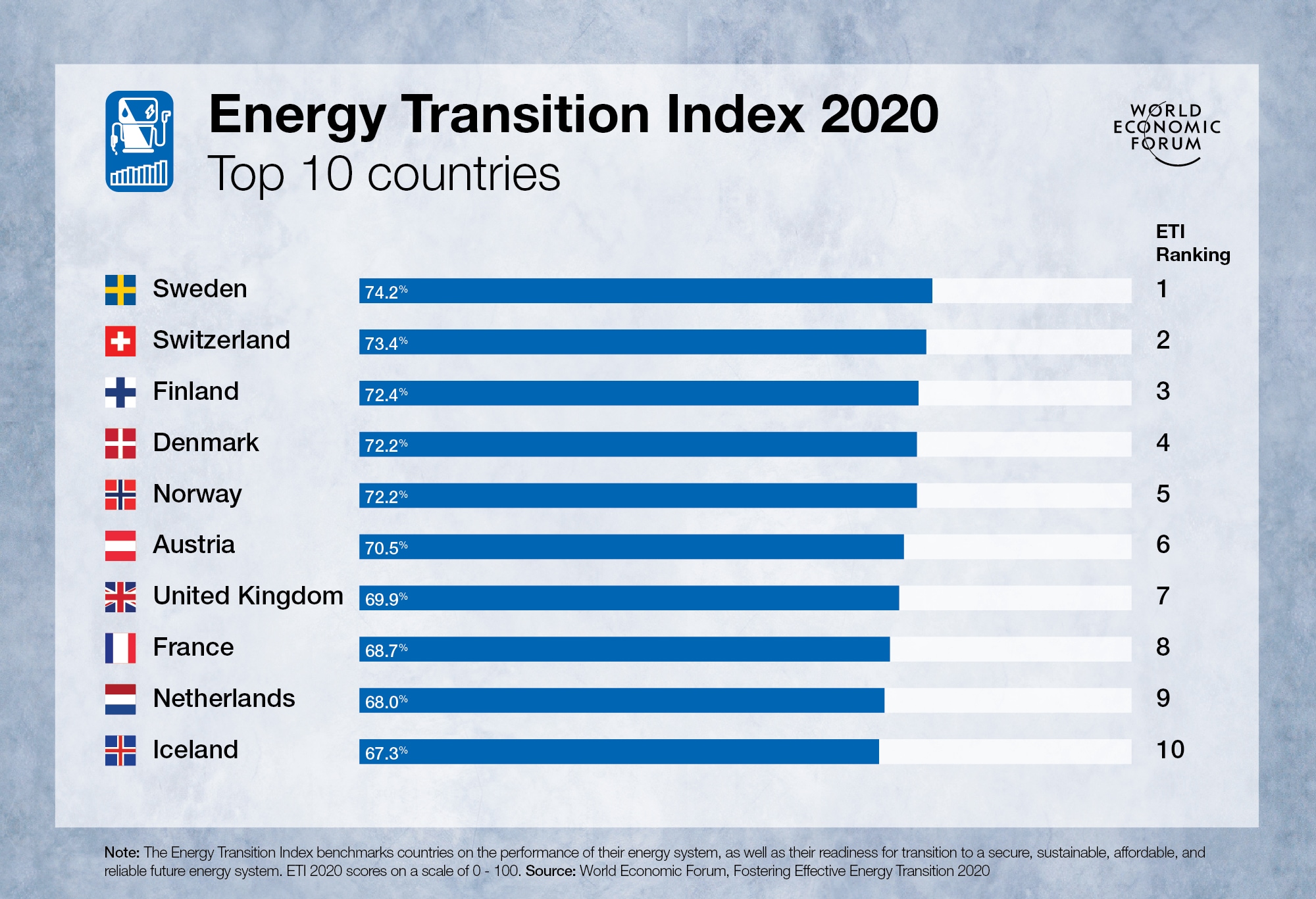

What's the World Economic Forum doing about the transition to clean energy?

As a next step, Wooley and Lutkenhaus have begun working in collaboration with Daniel Tabor, assistant professor in the chemistry department, through a 2020 Texas A&M Triads for Transformation (T3) grant that aims to utilize machine learning to optimize the materials and structure of the battery platform.

Alexandra Easley, a doctoral student in the materials science and engineering department, and Tan Nguyen, a former doctoral student from the chemistry department, now at the University of Michigan, are the study’s lead authors.

The National Science Foundation, the Welch Foundation, and the US Department of Energy Office of Science funded the work.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on BatteriesSee all

Kiva Allgood and Na Na

March 22, 2024

Johnny Wood

February 29, 2024

Stefan Milne-U

October 6, 2023

Dr Amit Jain, Dr Gabriela Elizondo Azuela and Aakarshan Vaid

September 5, 2023

Emma Charlton

August 30, 2023