4 fixes for equipment supply chains before the next COVID-19 waves hit

Tonnes of supplies of personal protective equipment (PPE) were sent to Italy from Guangzhou, China to help the southern Italian region of Puglia combat a spread of the coronavirus disease (COVID-19) Image: REUTERS/Alessandro Garofalo

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

Blockchain

- The COVID-19 crises forced governments to build new international supply chains nearly overnight.

- New innovations, such as blockchain, can make the supply chain more efficient, less risky and increase the velocity of goods running through the system.

- Supply chain solutions must be put in place now to help manage demand from second and third waves of infection.

When hospitals and governments first set up supply chains for COVID-19 equipment a few months ago, the emergency nature of the situation and lack of existing infrastructure meant very little coordination of the purchasing and distribution of vital goods. The overwhelming demand for personal protective equipment (PPE) in particular could not be met with stockpiles or well-established medical supply chains with large medical equipment vendors. Rather, pockets of available PPE had to be sourced, vetted, tracked, financed, and, in many cases, imported from overseas. In other words, governments had to build new international supply chains.

Leveraging established methods for managing supply chain logistics and risks, most governments were able to send a pipeline of equipment to health care providers. Along the way, there were massive delays, shortages, supplier scams, confiscated orders and general inefficiency that cannot be repeated when the second wave of COVID-19 hits in the late summer. Governments and hospitals should use this window of opportunity to implement new innovations that we know will make the supply chain more efficient, less risky and increase the velocity of goods running through the system. For that matter, these lessons can be applied not just to COVID-19 supply chains, but to any supply chain that is scrambling to get its operations back on track after massive disruption.

What is the World Economic Forum doing about the coronavirus outbreak?

1) Inject liquidity into the system. Small-midsize enterprises are crucial to plugging gaps in PPE supply and are far more limber than large suppliers whose PPE sales are now heavily regulated. Some of these smaller suppliers are new to the medical supply chain while others have related lines of business. Almost all struggled to obtain supply chain finance to support their fulfillment of PPE orders.

These businesses are financially squeezed between customers being unable to pay quickly and upstream suppliers demanding early payment for highly desirable goods. Traditional supply chain finance products, which rely on a close banking relationship with the supplier and/or the buyer, take time to execute. Cost can also be an issue since PPE margins are becoming thinner with the increased scrutiny of pricing. Faster sources of cash flow for suppliers that protect buyers are needed in case the suppliers are not able to deliver the goods.

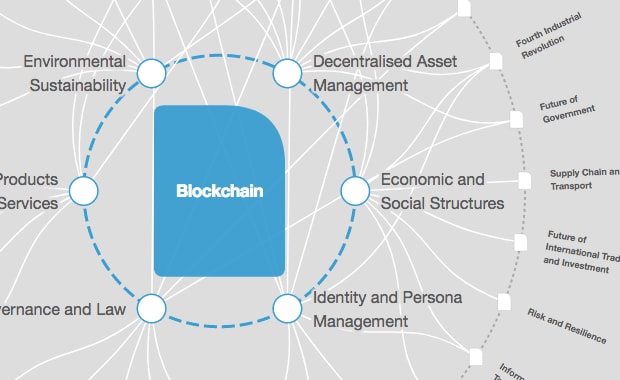

Blockchain can help manage these transactions across several financiers, depending on their risk tolerance. A blockchain monitors the performance history of transactions for transparency on information that may affect future financings. Consistent performance means lower cost of administering transactions and lower financing costs to reflect reduced risk.

Additionally, governments can place their purchase orders or approve their supplier’s invoices on a blockchain, which certifies to financiers that the suppliers have a legitimate order without requiring buyers to pay for a guarantee or pledge to buy PPE that ends up being faulty or never gets delivered. Financiers with a higher risk tolerance, such as investment funds, can monitor the use of their capital for the fulfillment of the orders. Banks, who are more risk-averse, can provide invoice financing and guarantees where needed.

Such approaches are already in development. Florida's Miami-Dade county is working with teams at Skuchain to deploy a financing solution for COVID-19 equipment as well as economic recovery efforts. The additional liquidity will facilitate the supply of PPE and support local businesses as they rebuild. The solution will benefit small business owners, especially minority-owned companies or firms in disadvantaged areas. “We are trying to explore innovative methods," said Manny Gonzalez, Trade Commissioner for Miami-Dade County.

"New innovations will make the supply chain more efficient, less risky and increase the velocity of goods running through the system."

”2) Incentivize data sharing. Health care providers and government agencies need to aggregate information from suppliers about the equipment they're sending to know exactly what inventory is on hand, how quickly it can be replenished and where it is going. It is not enough to analyze data sets produced by current technology. More comprehensive authenticated and accurate data from the supply chain is needed at the very start.

Suppliers are reluctant to send their data because they are concerned that commercially-sensitive information will become available to others in the supply chain ecosystem who shouldn’t see it. We need to reduce the infrastructure burden and allow suppliers to independently audit what information is being shared and with whom. A decentralized blockchain network, where each supplier can participate without owning a node, accomplishes this goal.

3) Build relationships with good suppliers quickly. In a highly competitive market, supplier relationships become key to guaranteeing a steady supply of goods. Therefore, information used to source and vet suppliers becomes an even-more closely held secret. However, in order to ensure a more efficient and frictionless market for PPE, suppliers should not have to go through a discrete vetting process every time they are selling to a new buyer or obtaining a new line of financing. That adds crucial weeks that an emergency supply chain cannot afford.

Suppliers should have the ability to easily share their information with others if they so choose. By placing their company data and performance history on a blockchain, suppliers can send this authenticated and immutable data to new counterparties, even if the latter are not currently a blockchain network themselves.

4) Set up program buying. To guarantee access to PPE supplies, countries took a number of drastic measures, including buying overseas factories. Short of such measures, governments and hospitals can lock the supply of critical components by administering program buying procurement. This supply chain management technique entails arranging quotas of goods from suppliers that are automatically replenished when inventory stocks are running low.

Program buying requires visibility into the shipment and depletion of inventory. Setting up visibility tools on both the demand and supply side requires months, so that process needs to be underway now to meet a potential COVID-19 resurgence. The alternative is to stick with the marketplace methodology that was used for the current COVID-19 crisis, in which matches between supply and demand were made in a much more ad hoc manner.

Experts are predicting that the second wave of COVID-19 will be worse because governments will decide, rightly, that the economy cannot survive another long period of lockdown. As a result, hospital systems need to be prepared for a larger wave of cases. The supply chain for PPE needs to be fixed now to make sure we can take care of those who contract COVID-19 and the essential workers who will have to continue coming into close contact with others during a pandemic.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Emerging TechnologiesSee all

Thomas Beckley and Ross Genovese

April 25, 2024

Robin Pomeroy

April 25, 2024

Beena Ammanath

April 25, 2024

Vincenzo Ventricelli

April 25, 2024

Muath Alduhishy

April 25, 2024

Agustina Callegari and Daniel Dobrygowski

April 24, 2024