These biodegradable plastics made from algae are a new hope for the environment

Scientists have created biodegradable plastics from spirulina, a blue-green algae that is already used in cosmetics and foods. Image: Pexels/Catherine Sheila

Cristen Hemingway Jaynes

Environmental Journalist, EcoWatch

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

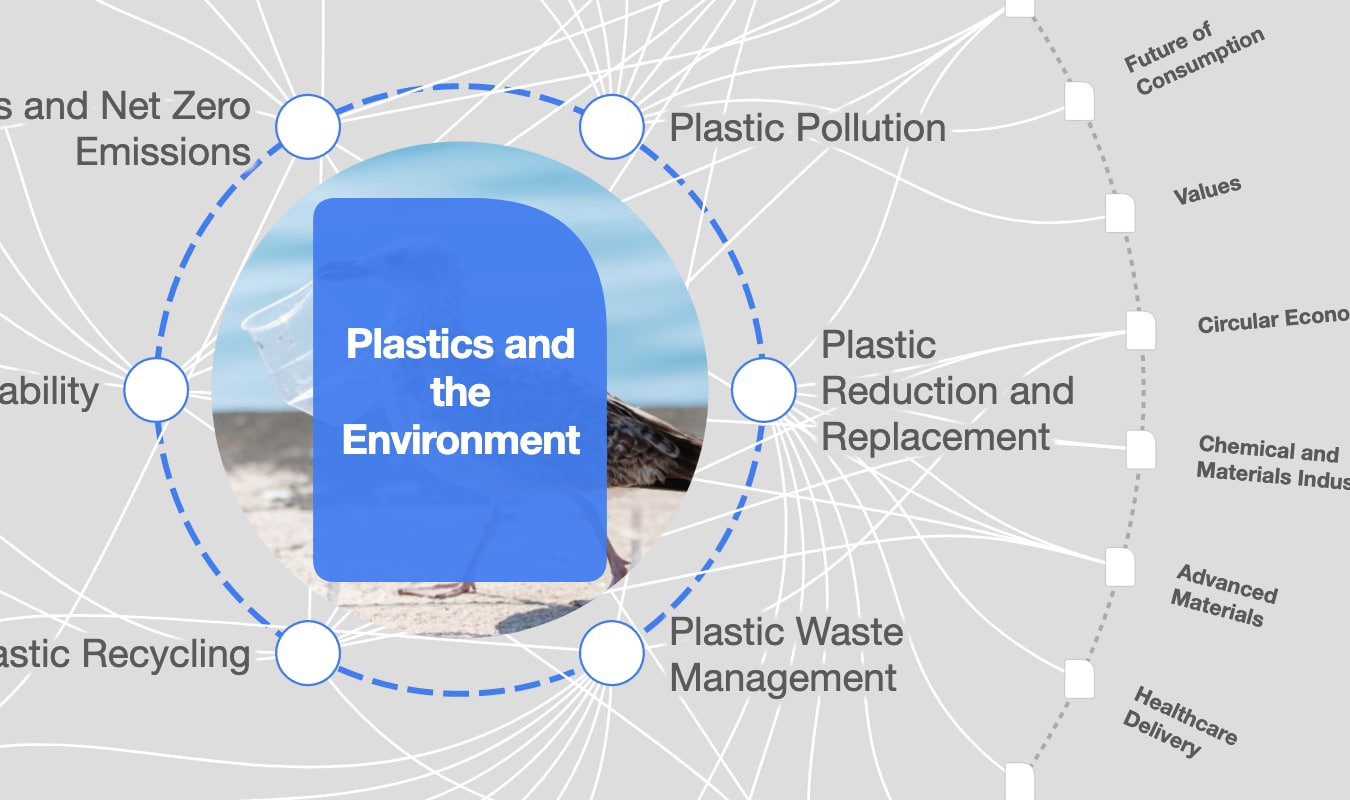

Plastics and the Environment

- Scientists have created biodegradable plastics from spirulina, a blue-green algae that is already used in cosmetics and foods.

- Spirulina is a good choice for bioplastics because it is carbon neutral and can be cultivated on a large scale.

- The mechanical properties of spirulina plastics are similar to single-use plastics derived from petroleum.

- However, more research is needed to develop spirulina plastics on a commercial scale.

Plastics are everywhere. They’re used to make food packaging, bags, water bottles and for many other common applications. As they break down, their tiny particles — known as microplastics — end up in the ocean, on the highest mountaintops, in our lungs and in our blood.

The problem with plastics is that they stay in the environment for years, posing hazards for humans, animals and the environment. But what if there were a different kind of plastic that would biodegrade in your backyard compost bin about as quickly as a banana peel?

A group of researchers led by scientists at the University of Washington have come up with new bioplastics that biodegrade naturally and relatively quickly — unlike traditional plastics, which do not biodegrade, or other types of bioplastics, which need to be processed in commercial facilities in order to biodegrade — and they’re made from the cells of the blue-green cyanobacteria known as spirulina.

What is the World Economic Forum doing about plastic pollution?

“We were motivated to create bioplastics that are both bio-derived and biodegradable in our backyards, while also being processable, scalable and recyclable,” said senior author of the study Eleftheria Roumeli, a UW assistant professor of materials science and engineering, in a press release from the University of Washington. “The bioplastics we have developed, using only spirulina, not only have a degradation profile similar to organic waste, but also are on average 10 times stronger and stiffer than previously reported spirulina bioplastics. These properties open up new possibilities for the practical application of spirulina-based plastics in various industries, including disposable food packaging or household plastics, such as bottles or trays.”

For the study, the researchers formed spirulina powder into a multitude of shapes using heat and pressure, which is the same way conventional plastics are processed and created. The mechanical properties of the spirulina plastics are similar to single-use plastics derived from petroleum.

The study, “Fabricating Strong and Stiff Bioplastics from Whole Spirulina Cells,” was published in the journal Advanced Functional Materials.

The scientists chose spirulina for their bioplastics because it is already being used for cosmetics and foods and can be cultivated on a large scale. As they grow, spirulina cells also sequester carbon dioxide, which means as a raw material for plastics spirulina is not only carbon neutral, but has the potential to be carbon negative.

“Spirulina also has unique fire-resistant properties,” said lead author of the study Hareesh Iyer, a UW materials science and engineering doctoral student, in the press release. “When exposed to fire, it instantly self-extinguishes, unlike many traditional plastics that either combust or melt. This fire-resistant characteristic makes spirulina-based plastics advantageous for applications where traditional plastics may not be suitable due to their flammability. One example could be plastic racks in data centers because the systems that are used to keep the servers cool can get very hot.”

Because the research team used a similar processing approach as traditional plastics with their bioplastics, large-scale manufacturing of the spirulina-based materials would be easier.

“This means that we would not have to redesign manufacturing lines from scratch if we wanted to use our materials at industrial scales,” Roumeli said. “We’ve removed one of the common barriers between the lab and scaling up to meet industrial demand. For example, many bioplastics are made from molecules that are extracted from biomass, such as seaweed, and mixed with performance modifiers before being cast into films. This process requires the materials to be in the form of a solution prior to casting, and this is not scalable.”

Making bioplastics out of spirulina has been done before, but the bioplastics the UW-led research team came up with are stiffer and stronger. They are also recyclable. The researchers changed processing conditions like time, pressure and temperature to improve the bonding and microstructure within the bioplastics, studying their stiffness, toughness and strength along the way.

The plastics still have some hurdles before they will be ready for industrial use, like being sensitive to water and somewhat brittle.

“You wouldn’t want these materials to get rained on,” Iyer said in the press release.

The researchers are still examining the bioplastics’ fundamental principles, and hope to create an assortment of bioplastics for various uses, similar to petroleum-based plastics.

“Biodegradation is not our preferred end-of-life scenario,” Roumeli said. “Our spirulina bioplastics are recyclable through mechanical recycling, which is very accessible. People don’t often recycle plastics, however, so it’s an added bonus that our bioplastics do degrade quickly in the environment.”

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Nature and BiodiversitySee all

Lena McKnight and Stefan Fahrni

May 2, 2024

Cristen Hemingway Jaynes

April 30, 2024

Robin Pomeroy and Linda Lacina

April 29, 2024

Greg Goodwin and John Stackhouse

April 29, 2024

Diego Vincenzi

April 29, 2024