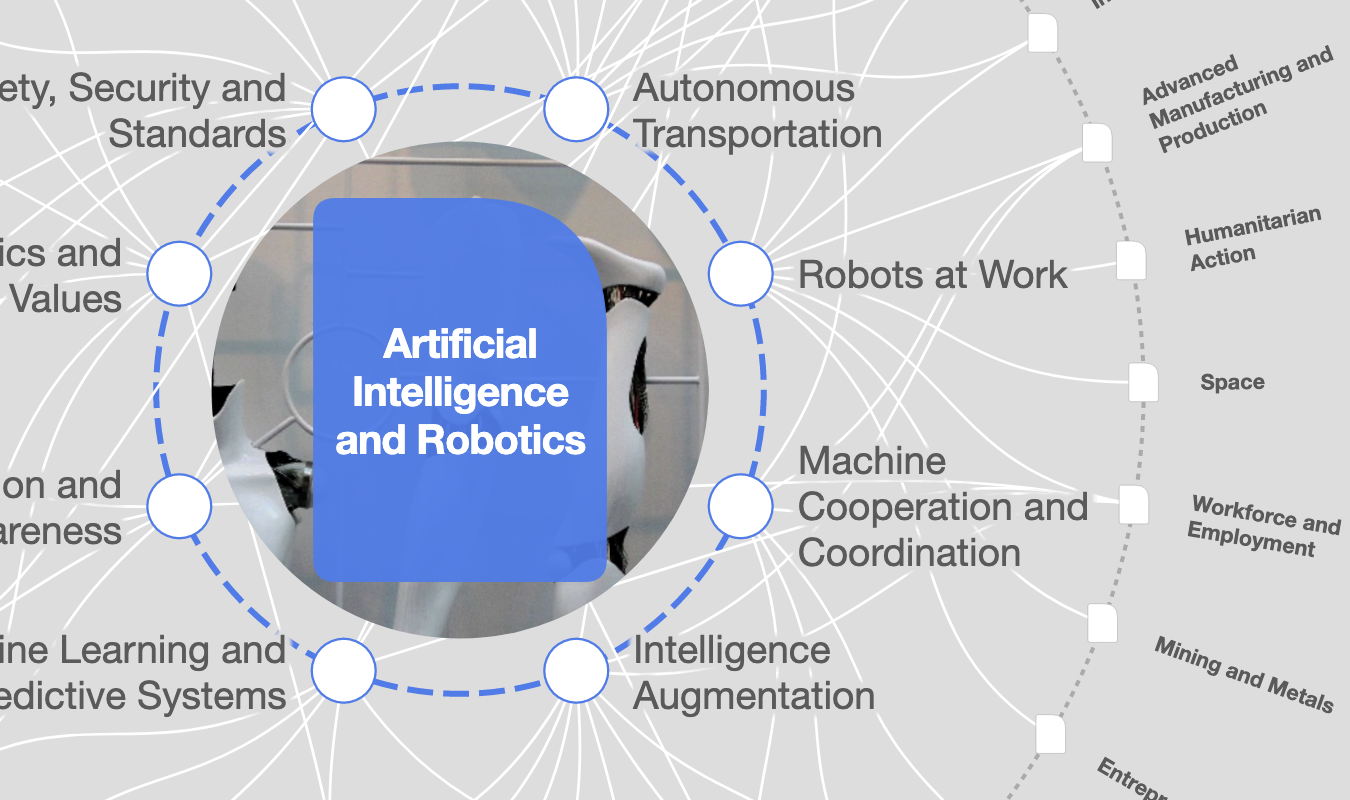

Can robots improve export quality in developing countries?

"One potential upside of automation is that robots consistently perform tasks to greater precision than human workers". Image: REUTERS/Rebecca Cook

Timothy DeStefano

Economist, Harvard Business School, Laboratory for Innovation Science at Harvard (LISH)

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

Technological Transformation

- Some media articles suggest that as rich countries automate, developing countries might lose out.

- However, robots are quickly becoming a part of manufacturing in many developing countries.

- The World Bank has created a working paper which explores the advantages of incorporating robots into developed and developing countries.

- It emphasizes the importance of diffusing a range of technologies and not just the most advanced ones, particularly in developing countries.

A rising chorus of media articles highlight how rich countries are rapidly automating and that developing countries may lose out – jeopardizing the future of manufacturing-led development. Yet, robots are in fact rapidly becoming a part of manufacturing in many developing countries. Of course, technology always presents new opportunities as well as challenges. One potential upside of automation is that robots consistently perform tasks to greater precision than human workers, which can reduce production errors and increase product quality. In a recent working paper we examine whether robots lead to export quality upgrading and the potential gains for both developed and developing countries.

The high standards of global value chains

A tide of automation is rippling throughout supply chains, with manufacturing in both rich and poor countries caught in the swell. Robot use in developing countries has increased nearly 10-fold over 2000-2015, outpacing growth in the labor supply. For example, Chinese manufacturing employed less than 1 robot per 1000 workers in 2000, rising to more than 80 by 2015. Robots are not only diffusing fast in China but also in several developing economies: by 2015 Brazil, India and Thailand had more robots than the average rich country. We find that suppliers adopt robots because of pressures from foreign customers that have automated themselves. Automation is now cascading throughout global value chains (GVCs).

While joining global value chains offers the potential of productivity growth and high-wage employment, quality standards can prevent poor countries from participating. Developing country manufacturing can indeed be plagued by poor production quality, therefore, hampering their access to export markets. In our data, developed country exports are on average around 60% higher quality than developing country exports. Foreign customers demand high quality products and these stringent quality standards are passed down supply chains. Firms that cannot meet these standards may miss out.

To err is human - can robots help?

While robots may replace some worker tasks, one potential upside is reducing human errors in production. Robots perform tasks repeatably to the same high-level of accuracy, so are commonly used in the assembly of small electronic components, precision welding of car parts or cutting of metals. Some types of advanced robots are able to operate within extremely accurate tolerances, for instance, those with lasers can cut to within 10 micrometers (0.01 millimeters). We find that automating leads to larger quality gains for initially lower-quality products. Since developing countries tend to produce lower quality goods, poorer countries have bigger quality gains from robot technology.

How is the World Economic Forum ensuring the responsible use of technology?

Policy implications

First, technology always creates winners and losers. While automation poses risks to some workers and firms, for others – especially in developing countries – it presents opportunities to upgrade quality, reach new export markets, and create productive employment. Policy should allow such firms to grow, for example by lowering labor market rigidities, which may help to offset any negative effects of declining firms and sectors. Second, our findings warn that growing trade protectionism may slow cross-border technology diffusion. It may constrain the ability of firms in developing countries to upgrade production processes, move into higher value-added activities and produce the high-quality products demanded by consumers. Finally, there is no one-size fits all recipe for policy since different production technologies are appropriate for different firms and countries. We find that not every country adopts the same types of robots. While the diffusion of new technologies is important for improving product quality, policymakers shouldn’t encourage only the most advanced technologies, especially in developing economies.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Emerging TechnologiesSee all

Thomas Beckley and Ross Genovese

April 25, 2024

Robin Pomeroy

April 25, 2024

Beena Ammanath

April 25, 2024

Muath Alduhishy

April 25, 2024

Vincenzo Ventricelli

April 25, 2024

Agustina Callegari and Daniel Dobrygowski

April 24, 2024