Why Large Language Models are the future of manufacturing

Large Language Models (LLMs) are set to change the manufacturing industry forever by acting as a conversational gateway between humans and machines. Image: Getty Images/iStockphoto

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

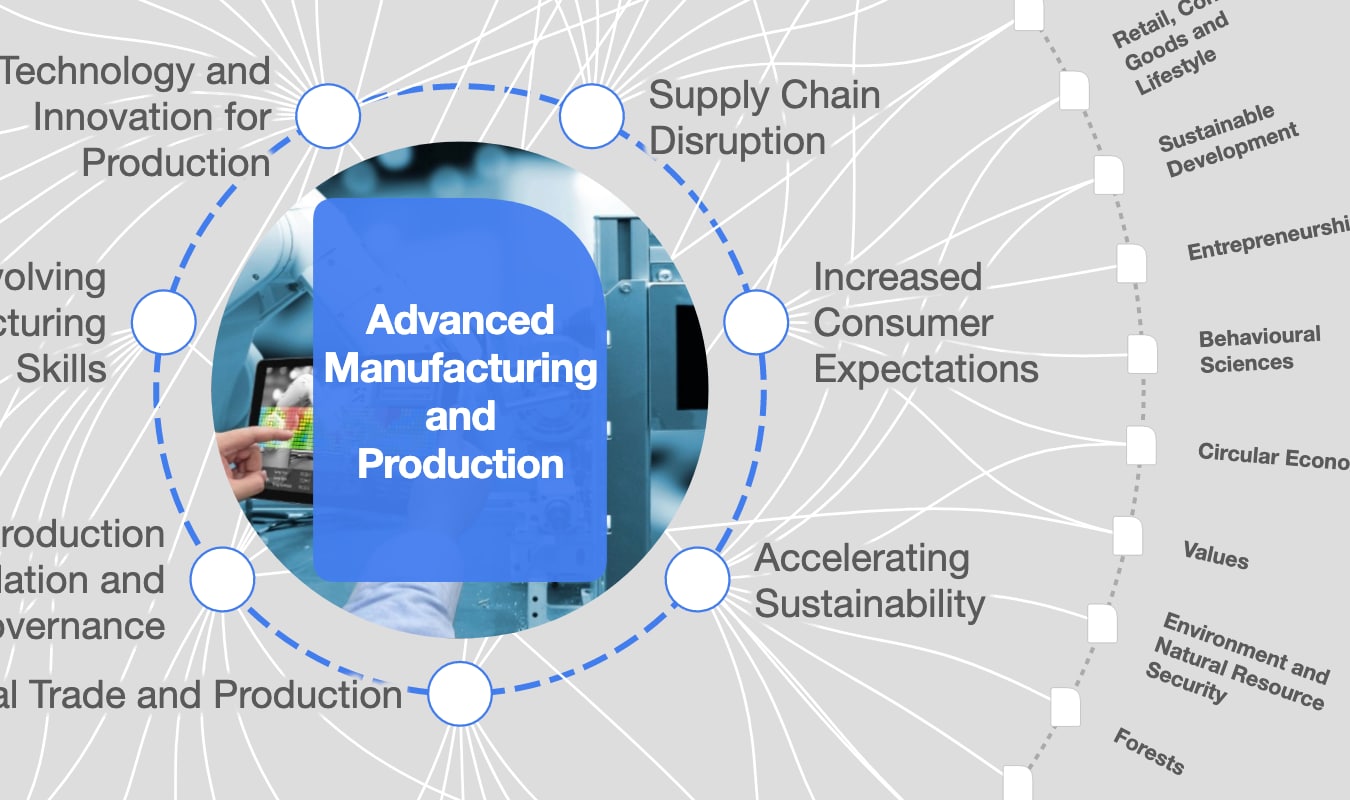

Advanced Manufacturing

- Large Language Models are set to disrupt industries the world over. For manufacturing, they will bridge potential knowledge gaps and manage databases that humans could not.

- They will serve as a conversational gateway between humans and machines, allowing businesses to unlock previously unknown potentials.

- Large Language Models are required to fully reflect the complex, domain-specific needs of the manufacturing industry.

We stand on the brink of a new era, fueled by the rapid advancement and integration of Artificial Intelligence (AI). Today, the manufacturing industry is poised to undergo a transformation unlike any it has seen before.

While the transition from manual labor to automated processes marked a significant leap, and the digital revolution of enterprise resource management systems brought about considerable efficiencies, the advent of AI promises to redefine the landscape of manufacturing with even greater impact.

Central to this transformation are Large Language Models (LLMs) and generative AI technologies. These tools are significantly lowering the barrier to entry for subject matter experts and field engineers who traditionally have not been involved in coding or "speaking AI." The impact of this should not be underestimated. Up to 40% of working hours across industries could be influenced by the adoption of LLMs, a significant shift in workforce dynamics.

AI, and particularly LLMs, will have a profound impact on the manufacturing sector. The opportunities are vast — but there are potential challenges, too.

The impact of AI on manufacturing

AI is reshaping the very fabric of manufacturing, transforming traditional automation frameworks and aligning them with ISA-95 standards at every level. This new era of automation heralds increased productivity and the emergence of innovative manufacturing practices, all driven by AI.

The integration of hardware automation, spearheaded by advances in robotics, combined with software automation led by AI, is crucial to unleashing the full potential of these innovations.

Yet, despite these advancements, AI remains an alien concept to many within the manufacturing industry. Subject matter experts, the seasoned engineers who intuitively understand machinery and production processes, find themselves at a crossroads. As these experts retire, their invaluable knowledge and insights risk being lost, underscoring the need for AI's integration into manufacturing to bridge this gap.

LLMs: The gateway between humans and machines

LLMs are set to revolutionize the manufacturing industry by serving as a conversational gateway between humans and machines, enabling assets and machinery to "communicate" with humans.

By interpreting vast amounts of manufacturing data, LLMs facilitate informed decision-making and pave the way for the future use of natural language in production and management.

This symbiotic relationship between AI and humans enhances the intelligence and efficiency of both parties, promising a future where AI's impact on manufacturing is more transformative than the industrial revolutions of the past.

In this future, AI amplifies human expertise, creating a collaborative environment where decision-making is faster, more accurate and informed by insights drawn from data that was previously inaccessible or incomprehensible.

The integration of AI into manufacturing extends beyond simple automation, encompassing areas like control optimization. By analyzing vast datasets, AI enhances production efficiency and reduces costs through the optimization of manufacturing processes. This not only smooths operations but also minimizes resource waste.

Reflecting the importance of these technological advancements, research shows that 75% of advanced manufacturing companies prioritize adopting AI in their engineering and R&D strategies. This commitment underscores AI’s key role in the future of manufacturing, guiding the sector toward more efficient and sustainable practices.

In the not-too-distant future, AI will be able to manage and optimize the entire plant or shopfloor. By analyzing and interpreting insights at all digital levels—from raw data, data from enterprise and control systems, and results of AI models utilizing such data—an LLM agent will be able to govern and control the entire manufacturing process.

How to make AI in manufacturing a success

For AI and LLMs to truly transform manufacturing, they must first be tailored to specific domains. This customization requires not only connecting to the right data sources but also developing tools for effective prompting that align with the unique challenges and processes of each manufacturing sector.

Domain specificity ensures that AI solutions are relevant, practical and capable of addressing the nuanced demands of different manufacturing environments. This demonstrates the need for industrial LLMs (or domain-specific LLMs) for proper and accurate application of LLMs in manufacturing.

In addition to domain-specific tailoring, the widespread and successful adoption of AI in manufacturing necessitates standardized development and operational processes. Establishing common frameworks and protocols for the implementation of AI technologies is critical to ensure compatibility, interoperability and security across different systems and platforms.

Standardization also facilitates easier adoption and integration of AI technologies, helping manufacturers to navigate the transition to AI-powered operations with greater ease and efficiency.

Maximizing the potential benefits of AI

The AI transformation in manufacturing is set to usher in an unprecedented level of innovation. To keep pace with this rapid advancement, manufacturing leaders must make timely and informed decisions.

Preparing for this shift means implementing organization-wide AI transformation initiatives to standardize the AI development and operations processes and laying the foundation to fully leverage the benefits AI offers.

As the manufacturing industry stands at the cusp of this new era, the integration of AI promises to bridge the gap left by retiring experts and propel the sector towards a future of unparalleled efficiency and innovation.

The journey towards AI-enabled manufacturing is complex and fraught with challenges, but the potential rewards make it an endeavor worth pursuing.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Manufacturing and Value ChainsSee all

Aleksander Ciszek and Devin Culham

April 25, 2024

Andrea Willige

March 19, 2024