This start-up recovers metals from waste through ‘molecular recognition’

ChemFinity’s nano-sponge filters recover metals from waste with 99% efficiency, offering a low-carbon alternative to traditional mining.

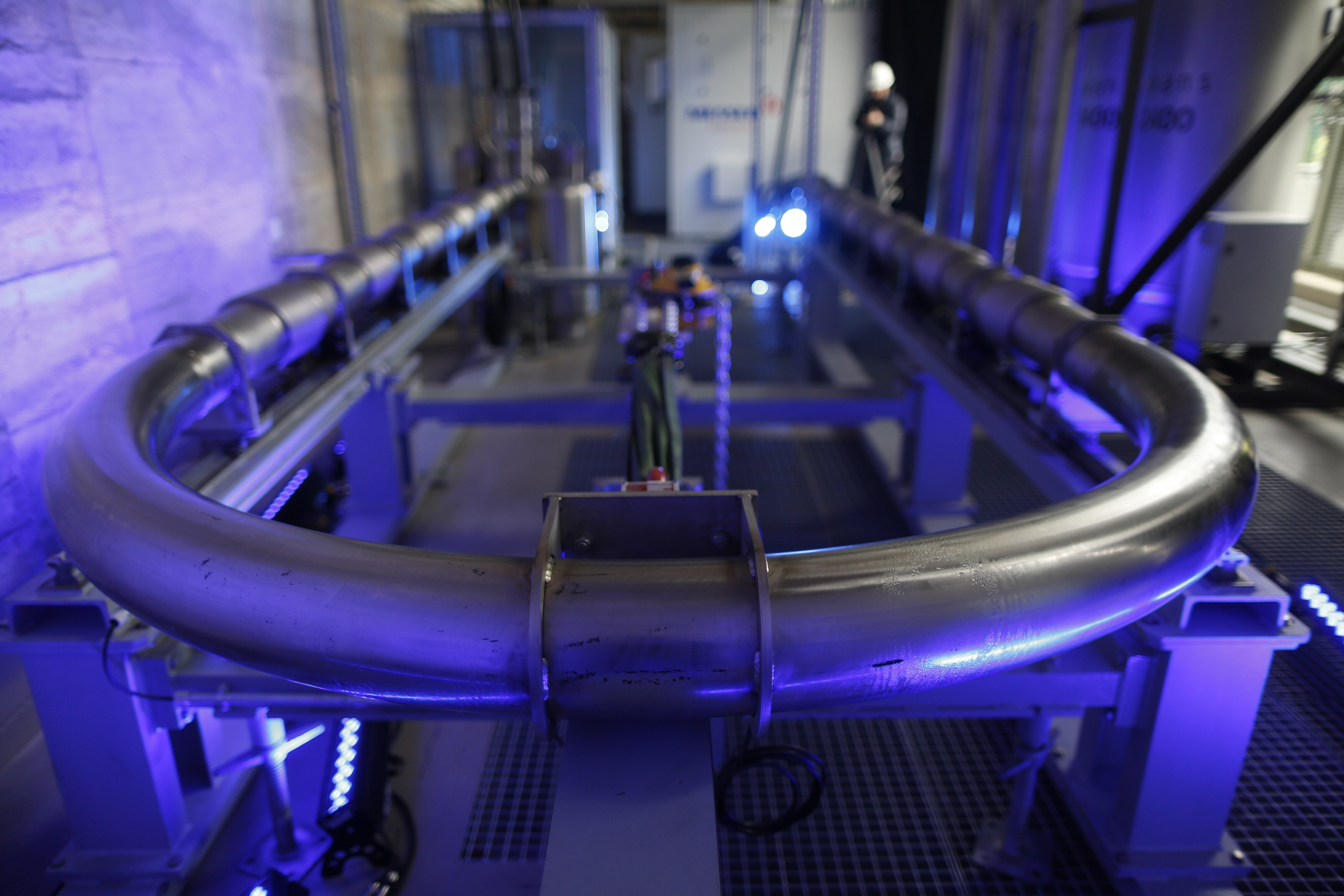

A start-up called ChemFinity is pioneering a new approach to sourcing critical minerals. Using a technique known as molecular recognition, the company recovers valuable metals from waste using specially engineered nano-sponges.

How nano-sponges rescue metals

These nano-sponges act as chemical binders that selectively attach to metals dissolved in waste streams. The system can recover up to 99 percent of valuable metals with no detectable impurities, across materials ranging from e-waste to engine parts and mining tailings.

Cheaper, cleaner, and more circular

ChemFinity’s process can extract over 20 different minerals at a third of the cost of traditional mining. It also emits up to 100 times less carbon. This offers a low-impact alternative at a time when mining is responsible for up to 7 percent of global greenhouse gas emissions.

Unlocking critical minerals from landfill

While the energy transition depends on rare earths, platinum, and other metals, just 22 percent of e-waste is currently recycled. ChemFinity aims to turn waste into a resource, preventing valuable materials from ending up in landfill.

A sustainable solution for the energy transition

As a winner of UpLink’s Sustainable Mining Challenge, ChemFinity is helping accelerate the shift toward circular, low-emissions mineral sourcing. Their innovation supports the growing demand for critical materials without adding to the environmental burden.

Watch the video to see how molecular recognition could transform the future of mining.

Topics:

Technological InnovationForum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.