This electronics manufacturing company changed its operations to make coronavirus medical supplies

With supply chains stretched to the limit, gestures like this are well needed and can help save lives. Image: Unsplash/Han Chenxu

- Adafruit, an electronics manufacturing company based in New York City, responded to a call for help from local officials.

- The company is now using its 50,000-square-foot factory to make medical devices and PPE.

- "We're just heads down and focusing on helping our city get through this," founder and lead engineer Limor Fried told Business Insider.

Electronics manufacturing company Adafruit is putting its 50,000-square-foot factory in New York City to use for coronavirus crisis relief by building medical devices and PPE.

"We're just heads down and focusing on helping our city get through this," founder and lead engineer Limor Fried told Business Insider.

She launched Adafruit in 2005 to teach people how to hack and build electronics. Without taking a dime in funding, the company has since expanded into a one-stop shop for makers and hobbyists, selling equipment like Raspberry Pi batteries, cables, LEDs, sensors, and wearables, while doing in-house electronics repairs as well. Adafruit-powered creations are particularly popular at Burning Man, in both towering sculptures or funky light-up outfits.

Fried says Adafruit got involved in crisis relief after New York City officials put a call out for local manufacturing businesses to help the city deal with massive PPE and medical device shortages.

"Because we do production, laser cutting, all sorts of things that you need to do, we said 'Sure, sign us up,'" Adafruit managing director Phillip Torrone told Business Insider.

Just like that, the company started building and shipping goods like face shields, sensors for medical devices, digital thermometers, oximeters for taking finger pulses, and thermal cameras for fever screening. New York City officials have deemed it an "essential service," meaning that Adafruit can continue operating even as other businesses shut down.

"I hope we can do our part to help New York City and continue to help New York state and any eastern hot spots like New Jersey and Connecticut," Torrone said. "We want to make sure we can get electronics needed to other states and other countries."

Since Adafruit is currently focused on delivering medical equipment and PPE, it's relying on partners and distributors to send its usual products to customers that order them. That's not a particularly big load to fill right now though: Adafruit's sales have been down a stunning 90%, Torrone says. Usually, Adafruit ships about 30,000 orders every month, but it's slipped to about 3,000.

How Adafruit changed its operations

In order to operate efficiently and safely, Adafruit had to make some changes within its factory.

It staggered employee's shifts, and requires workers to use an onsite fever scanner when they arrive, and wear gloves and masks.

"It's just a matter of being deliberate with your staffing: how you staff, when you staff, and following very specific protocols to keep everyone safe," Torrone said.

While Adafruit has reduced some of its operations, it says there haven't been any layoffs and it's still paying all its team members and contractors. Although Adafruit's sales are down, people are still finding ways to build with its electronics, such as this DIY musical soap dispenser.

"We're all connected more than we ever have been," Torrone said. "The best outcome is, this is something we were able to do that helps a lot of people."

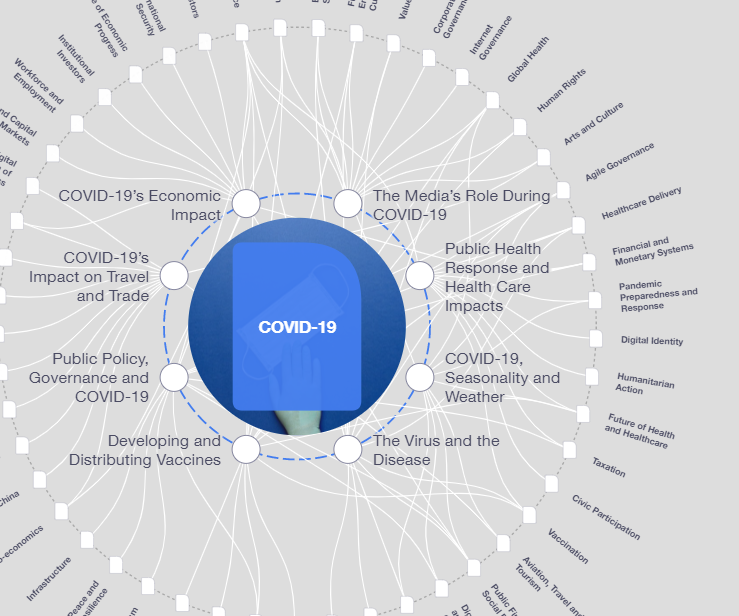

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

COVID-19

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Health and Healthcare SystemsSee all

Mansoor Al Mansoori and Noura Al Ghaithi

November 14, 2025