This Brazilian company can turn your trash into musical instruments

The world produces more than 400 million tonnes of plastics every year. Image: REUTERS/Amanda Perobelli

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

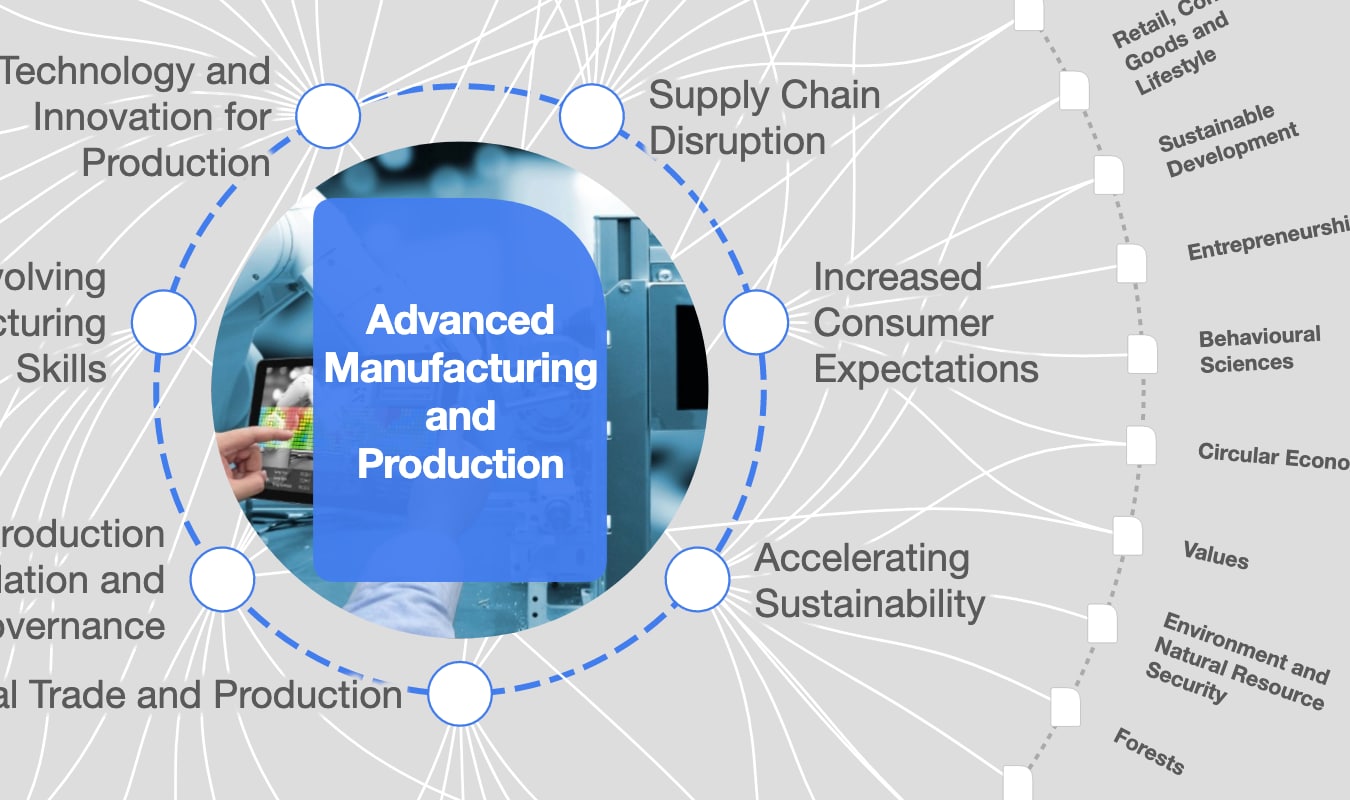

Advanced Manufacturing

- Brazil is the fourth biggest producer of plastic in the world.

- Mismanagement of waste globally means microplastics have now been found in drinking water.

- Boomera finds new uses for hard-to-recycle plastic products that normally end up in landfill.

- The company works with Brazil’s waste pickers and has found solutions for companies including Adidas and Nestlé.

What goes around, comes around. That famous saying about the way we treat others could equally apply to how we’re treating the planet.

The plastic waste we see littered on streets and clogging beaches is one of the more visible examples of human impact on the environment: but it’s now coming back around to haunt us.

Last summer, the World Health Organization called for urgent research into the health impact of microplastics, after particles were found in drinking water.

The world produces more than 400 million tonnes of plastics every year, much of which is mismanaged after use – with only 14-18% being formally recycled and more than half ending up in landfills.

Brazilian materials engineer, Guilherme Brammer, was so frustrated by the lack of adequate recycling he saw in his home city, São Paulo, that in 2011he set up a company looking for innovative solutions to give raw materials new life.

Mismanaged plastic waste

In 2010, Brazil produced an estimated 12 million tonnes of plastic – the fourth biggest producer in the world behind China, the US and Germany. At the same time, a study found 7.2% of the plastic waste in Latin America and the Caribbean was "mismanaged" – either being littered or disposed of inadequately, meaning it was more likely to wind up in the ocean.

“If it is difficult to ensure that materials that still have market value return to industry as raw material, what about waste without value?” Brammer, a Schwab Social Innovator of the Year 2019, told the Hindu.

“It ends up in garbage dumps or even landfill, where it stays for years, having hardly ever been used.”

Brammer created Boomera to find new ways to revive the value in, and reuse, the hard-to-recycle waste products that usually end up in landfill, such as disposable diapers, cigarette butts and coffee pods. The result is post-consumer recycled material (PCR).

Going round in circles

Boomera is an amalgamation of ‘boomerang’ and ‘woomera’, two Australian Aboriginal artifacts – one that comes back when thrown and the other a spear that lands with precision.

It is, quite literally, a revolutionary circular economy business that brings together industry, academia and environmental agents, while also involving research and development, product design and reverse logistics.

To date, it has found solutions for big companies including Procter & Gamble, Adidas and Nestlé.

For Nescafé’s Dolce Gusto, Boomera found a way to recycle the pods to create a new type of plastic resin, which now makes up to 15% of the material in capsule packaging trays.

What is a circular economy?

If a product/packaging has no technical recycling solution, it’s taken to Boomera’s circular engineering lab at the Mauá Institute of Technology in São Paulo for testing to analyze different recycling routes.

“Once the technical recycling of the material is solved, we develop the reverse logistics system that works best with the waste,” says Brammer.

In partnership with Dow, Boomera works with a network of waste picker cooperatives around Brazil to collect the waste material, bringing work to those communities.

In another project, schools collected waste drinks cartons, which were recycled into musical instruments.

“We need to turn what would be garbage into an actual business,” says Brammer.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Advanced ManufacturingSee all

Stephanie Wright, Memia Fendri and Kyle Winters

February 13, 2024

Maya Ben Dror and Lena McKnight

January 31, 2024

Dr. Matthew Putman

January 17, 2024

Kyriakos Triantafyllidis and Andreas Hauser

January 16, 2024