'Lighthouse' factories are more productive than ever. Business leaders explain how they do it

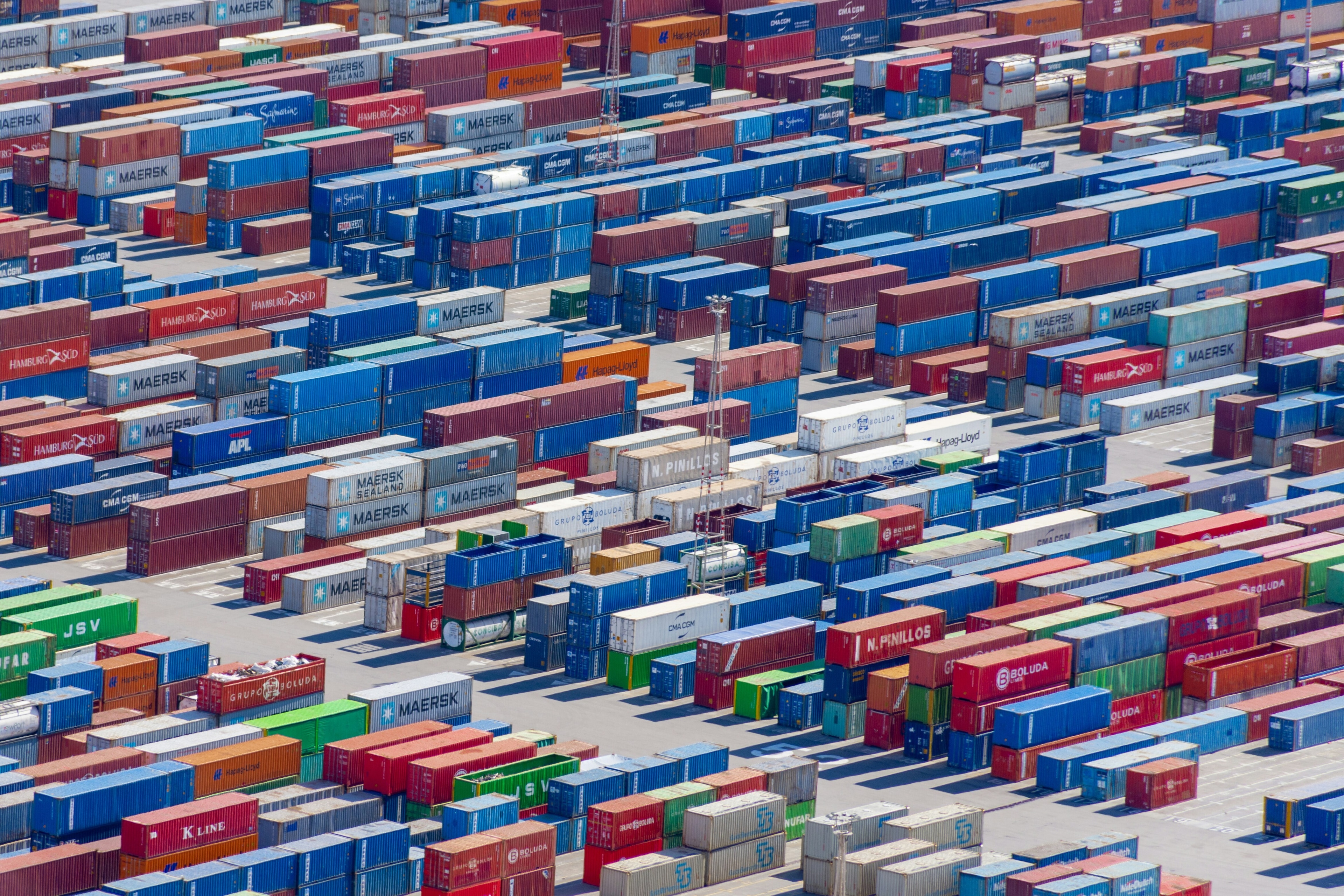

How do digitally-infused operations go beyond productivity gains to create sustainable, profitable growth? Image: Photo by ThisisEngineering RAEng on Unsplash

- Fifteen new organizations have joined the World Economic Forum’s Global Lighthouse Network as leaders in applying Fourth Industrial Revolution technologies like AI and digitalization, to achieve profitable growth without increasing their environmental footprint.

- There are now 69 factories and sites that are a part of the network, prioritizing digitalization and workforce skills development to protect jobs and build resiliency.

- Here, some of this year's Lighthouse leaders share insights into their strategies to scale up growth and find new revenue streams. You can also hear from company leaders today at "Lighthouses Live".

The Global Lighthouse Network has welcomed 15 new lighthouses to an inspiring group of organizations that demonstrate how digitally-infused operations go beyond productivity gains to create a base for sustainable, profitable growth.

These organizations have the courage to invest in new ideas, new approaches and altogether new methods that are collectively transforming the very nature of operations.

Despite growing complexities and disruptions, these companies continue to show signs of sustained strength. A new report shows that despite the COVID-19 pandemic’s unprecedented disruption, 93% of Global Lighthouse Network factories achieved an increase in product output and found new revenue streams.

They are achieving this by realizing productivity improvements, gaining market share, putting customers first and ushering in a cleaner future. These gains are being made with little to no capital expenditure and the forerunners are discovering that growth need not come at the expense of environmental responsibility. In fact, the opposite is taking place: productivity improvements often drive resource efficiency gains and are tied to environmentally-conscious impact.

So how do these organizations do it and what is their secret to scaling up? Here are insights from some of those driving the changes at Lighthouse organizations.

'Competitiveness'

Volkmar Denner, Chairman of the Board of Management, Bosch

Industry 4.0 and of course digital… is about the competitiveness of our plant. It's also clearly our productivity, cost reduction and quality improvement, but in the end it's about competitiveness.

'Skills renewal'

Börje Ekholm, President and CEO, Ericsson Group.

Here we really need to focus on the people, we need to upskill, we need to invest in training and developing our people to work in new ways and new agile ways of working, because that's going to ultimately be what makes the lighthouses successful if we are to roll them out at all sites.

'Sustainability a competitive advantage'

Carsten Knobel, CEO, Henkel

I’m convinced that especially for consumer industries, sustainability becomes a competitive advantage. The ecological footprint of our products and technologies becomes increasingly important for our customers but also for our consumers.

Industry 4.0 is a key lever to drive sustainable growth, to reach our long-term sustainability targets the Fourth Industrial Revolution technologies are key and we will continue to transform at a large scale.

'Digitalization touches every aspect of business'

Alex Gorsky, Chairman and CEO, Johnson & Johnson

Digitization is going to touch every aspect of our business… ten years from now, whether it´s our businesses, our manufacturing, our financial systems, our human resource systems – it will just be so imbued into every process, every function, every connection that we make.

We also believe that sustainability is absolutely an essential part of healthcare – because if we´re not creating … a cleaner environment, an environment that is more sustainable, if we´re not contributing to that – we’re not fulfilling our mission to improve healthcare for peoples’ lives around the world.

'Faster and better decisions'

Fang Hongbo, Chairman and CEO, Midea

(Digital transformation)… has changed how we do our business, actually on our whole value chain everything has changed …. at the highest level … it has changed our business model.

With the use of digital technology and the development of digital infrastructure we have been able to optimize all the data with better computation, with better algorithms we can make faster and better decisions.

What is the Forum doing to help companies achieve profitable growth without increasing their environmental footprint?

'Flexibility and enlightened leadership'

Satya Nadella, CEO, Microsoft

I don´t subscribe to any one dogma saying “we´ve found the future, this is the only thing” – I think we´ll all have to really adjust to what might feel in the initial phases as more complex – but the tools and the technologies and even leadership and management capabilities will help us overcome these challenges.

The key word is flexibility. There are three dimensions in which this flexibility will need to be supported: collaboration, learning and wellbeing. I´ll call it the next level of enlightened leadership in management and policies.

Around collaboration: the interesting thing will be the collaboration between front-line people and the knowledge folks. Like an engineer who is on a manufacturing site, who is working from home, talking to a technician on the frontline.

The way we approach learning and skilling is going to be structurally changed – and that, by the way will have great results around productivity going forward.

Wellbeing: we have to think about productivity narrowly not broadly – and this is another place where data … can be helpful, in terms of how we are allocating the most scarce resource – which is our time and attention.

'The latest and greatest in automation and digitalization'

Roland Busch, CEO, Siemens

I think leveraging a lean and digital transformation programme across our network, is essential.

If we want to stay ahead of competition, if we want to really help our customers make their transformation happen to stay relevant, we really have to ensure that we are coming up with the latest and greatest products in terms of automation and digitalization. And that means that we really have to also use our technologies in order to transform our own operations at the same time.

'Reverse mentoring'

T.V. Narendran, CEO and Managing Director, Tata Steel

There is a great opportunity to scale Fourth Industrial Revolution principles beyond the core functions… I think one of the areas which we can really enhance is the stakeholder experience through deploying 4IR technologies. Those stakeholders could be suppliers, those stakeholders could be customers, those stakeholders could be the employees, those stakeholders could be the community.

How do we transform the organization using the principles of what is relevant for the future? …. We also did a number of projects bottom-up, so that people on the shop floor saw the value in this journey for them. We tapped into the younger demographic in our companies because they were ahead of the older and more experienced people on this technology curve, so we did a lot of reverse mentoring, got them on board and they worked with the leaders.

'All the data… a 100% digital transformation'

Hsien-Ming Lin, Chairman and CSO, Wistron

The key is that the whole organization needs to impress the 100% digital transformation to all your data. Your database is nothing but truths. Then you need a very good data structure to highly utilize such data to analyse and then to make decision.

So that's also real-time data that is the fundamental big changes, not a single task, so the whole company need to convert to fully digital.

Related topics:

Contents

'Competitiveness''Skills renewal''Sustainability a competitive advantage''Digitalization touches every aspect of business''Faster and better decisions''Flexibility and enlightened leadership''The latest and greatest in automation and digitalization''Reverse mentoring''All the data… a 100% digital transformation'More on Manufacturing and Value ChainsSee all

Caroline Narich, Maria De Miguel, Jessika E. Trancik and Christine Gschwendtner

November 12, 2025