What is 'materials transition' and why is it critical for a net-zero future?

Carbon fiber reinforced polymers are increasingly being used to make large rotor blades for wind turbines. Image: Unsplash.

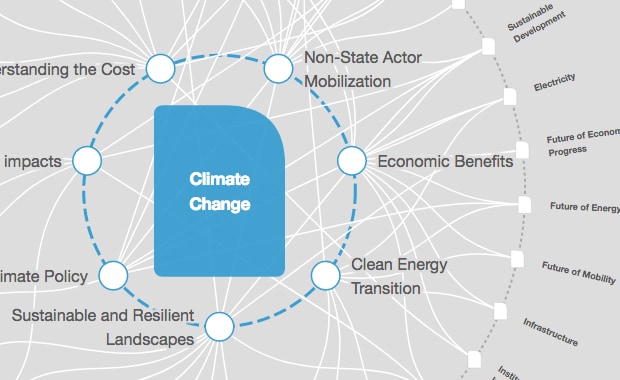

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

Climate Crisis

Listen to the article

- Climate mitigation efforts often overlook the emissions associated with the production and consumption of products.

- The materials transition aims to evolve the current materials landscape by inducing efficiency, substituting emission-intensive materials and enhancing its circularity.

- Materials transition will increase capacity for a scalable energy transition, while extending emissions-reduction efforts deep into products and applications.

The latest IPCC report made it clear that we have reached a “now or never” moment if we are to prevent climate breakdown and meet global climate goals. This warning comes despite years of investment and ambitious policies supporting the energy transition. Since 2010, annual global investments in energy transition grew by 100% to a total of $500 billion per year, the share of electricity generated from renewables grew up to 29%, and the cumulative number of global electric vehicles (EVs) on roads grew twenty-fold.

Furthermore, a first-of-its-kind blue ammonia shipment to Japan demonstrated the potential of hydrogen in zero-carbon power generation. Despite these efforts, global climate action is still inadequate to address the current climate crisis, according to the IPCC 2021 Sixth Assessment Report. At COP26 in Glasgow the next decade was labelled the one for action, in an invitation to scale-up climate deliverables. It is clear that "more" still needs to be done.

To date, climate mitigation efforts have focused primarily on reducing emissions that are associated narrowly with energy generation, while often overlooking the emissions associated with production of products and consumption activities; comprehensively across product value chains and throughout their life cycles. This missing systemwide perspective is the “more” that is needed to avert growing climate consequences.

Materials transition explained

Indeed, a paradigm shift for how we design, manufacture and deploy materials into these products is the other key form of transition through which this systemwide approach of tackling emissions is achieved. This “materials transition” aims at evolving the current materials landscape by enhancing materials-induced efficiency, reducing emission-intensive materials through material substitution, and expanding upon direct and indirect material reuse and circularity.

Materials-induced efficiency aims at replacing conventional materials with advanced ones that are far superior in terms of toughness, weight reduction and durability to extend a product’s lifetime and optimize its energy consumption. For example, using a glass fiber reinforced polymer (GFRP) as an alternative material to steel reinforced bars will extend the lifetime of a concrete structure and reduce the emissions associated with its installation, maintenance and replacement.

How is the World Economic Forum contributing to build resilient supply chains?

On the other hand, material substitution aims at replacing emissions-intensive materials with more sustainable ones, by eliminating the emissions associated with their manufacturing and production. This includes replacing steel, cement and glass with polymer concrete, fiberglass, engineered wood and mass timber in products and applications. Finally, the sustainability of this framework is anchored by materials circularity, in which materials and associated emissions are recycled and reused into products and forms of alternative energy, in accordance with the Carbon Circular Economy framework’s reuse, recycle and remove requirement.

Examples of sustainable materials in action

The breadth of sectors and applications in which these advanced and sustainable materials can be deployed is vast. A series of established applications and piloted demonstrations in sectors such as renewables, automotive, construction, packaging, electronics, appliances and agriculture have proven economic and sustainability gains. Below are some examples:

- Renewables: carbon fiber reinforced polymers (CFRPs) are being increasingly used to make large rotor blades for wind turbines. This deployment results in a 30% weight reduction, which ultimately results in more efficient energy generation. In addition, GE Renewable Energy and Veolia recently announced a move to recycle wind turbines into raw materials for cement manufacturing, which could result in a 27% reduction in associated cement production emissions. This deployment in the renewables sector showcases a comprehensive deployment of the “materials transition” framework, in which all pillars are depicted: efficiency, substitution and recycling/reuse.

- Building and construction sector: alternative concrete such as polymer concrete outperforms conventional ones in mechanical and thermal properties; it is 75% lighter and is advantageous in terms of chemical, corrosion and moisture penetration resistance. Again, this application exhibits two aspects of the materials transition framework: materials-induced efficiency (driven by substantially lower installation and maintenance energy requirements), and a material substitution that avoids a total of 72.5kg of carbon dioxide per ton compared to the heating and curing requirements of conventional concrete production.

- Automotive sector: pilot projects have shown that the environmental performance of vehicle light-weighting using CFRP has reduced life-cycle greenhouse gas (GHG) emissions by 12%. A next generation carbon-fiber composite could reduce passenger car weight by 50% and result in a nearly 35% improvement in fuel efficiency, according to a report published by the U.S. Department of Energy. This is another example of how a material’s induced efficiency and substitution of steel with CFPR promises substantial gains.

By enhancing energy consumption efficiency throughout product life cycles, and by offering an alternative and scalable substitute to emissions-intensive materials, the materials transition will further strengthen transitioning energy supply, while widening the emissions reduction pie by creating a parallel scheme of emissions reduction beyond energy generation, and more deeply into product and application value chains.

Socioeconomic benefits

In addition to its ability to support emissions reduction efforts, a scalable materials transition brings in substantial socioeconomic value, as it will create new economic activities and support societal development. This transition will help to secure the right materials base to enhance the efficiency of buildings and to scale up the deployment of renewables where it is mostly needed, in low-income societies, while offering direct and indirect jobs across sectors and along the value chain (design, production, application and recycling).

It will also help to accommodate the disruptive impact of the energy transition by repurposing jobs to serve other segments in product value chains. For instance, operators at fuel refining sectors can be easily reskilled to help produce the high-value primary chemicals needed to produce a wide set of these advanced sustainable materials.

What more can be done?

While the energy transition seeks to transform how we generate energy and how we consume it to achieve a low carbon emissions future, the materials transition will ultimately deploy multiple forms of carbon atoms to sustainably transform the way we use and reuse materials in energy supply and demand across the entire economy.

With these gains in mind, key questions need to be answered. What could possibly be the ultimate value of a fully synergized energy and materials transition? How can governments, institutions, companies and the public embrace this interdependency between energy and materials in an increasingly complex global system? How can we nurture this systemwide and full life-cycle perspective toward emissions and ensure this consistently overlooked blind spot is getting the attention it deserves?

Policymakers are well-advised to recognize the opportunities brought by the energy and materials interplay, and to embrace its driving forces, which can usher in a clear line of sight toward ample climate and socioeconomic gains.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Climate CrisisSee all

Mette Asmussen and Takahiro Furusaki

April 18, 2024

Laia Barbarà and Ameya Hadap

April 17, 2024

John Letzing

April 17, 2024

William Austin

April 17, 2024

Rebecca Geldard

April 17, 2024