This is the key for manufacturers to withstand future shocks

Image: Possessed Photography/Unsplash

Francisco Betti

Head, Global Industries Team; Member of the Executive Committee, World Economic ForumListen to the article

- The manufacturing industry faces threats from soaring energy prices, supply chain disruption and talent shortages.

- Scaling technological solutions can make the industry more efficient, sustainable and resilient.

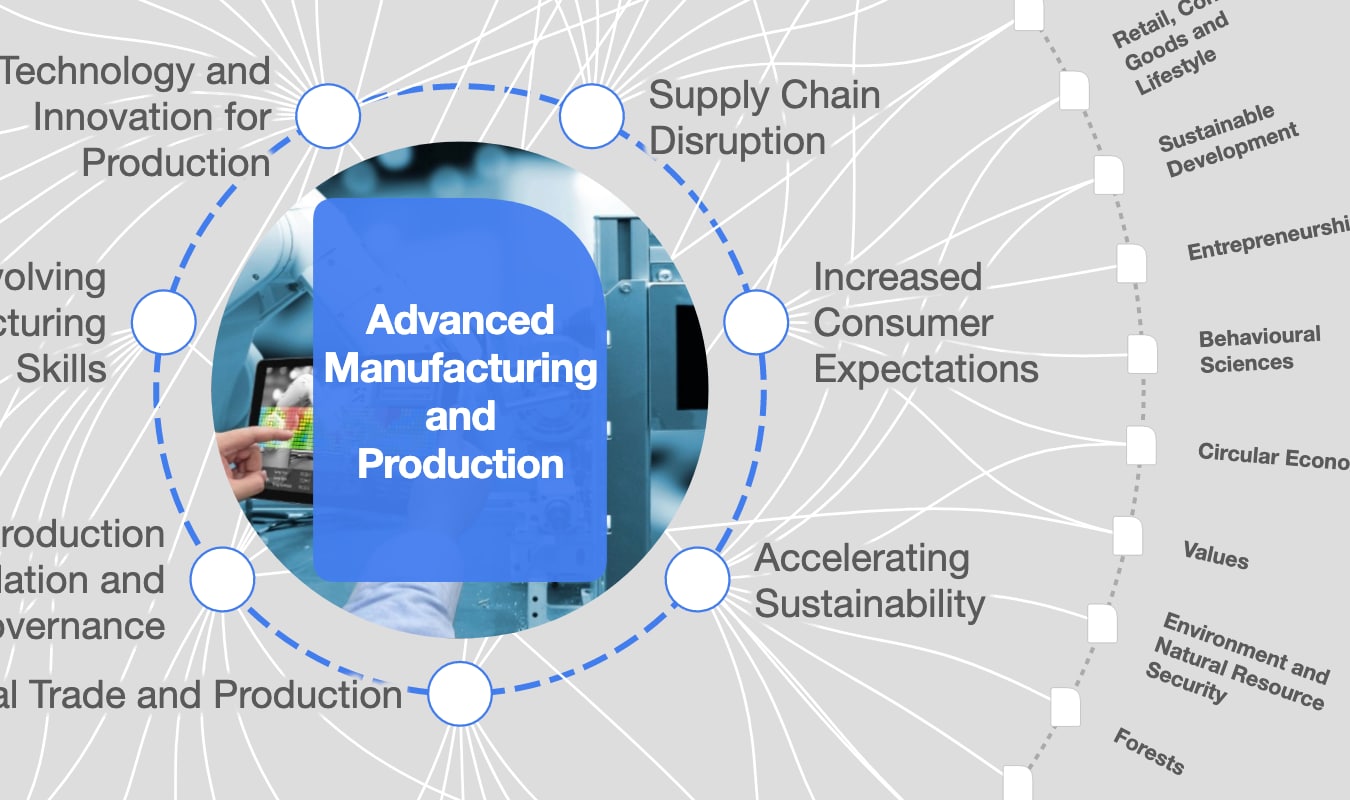

- Eleven new sites join the World Economic Forum's Global Lighthouse Network of manufacturers that are applying technology to unlock value and prioritize environmental sustainability.

The manufacturing industry is at a critical moment in its history.

The COVID-19 pandemic caused drastic upheavals to supply chains that continue today. Soaring energy prices and inflation and global talent shortages present immediate threats to productivity and progress. Meanwhile the growing impacts of climate change increase the pressure for longterm sustainable solutions.

The manufacturers who survive these challenges will be those who employ advanced technologies to drive growth, sustainability and resilience. Those who effectively scale these technologies will be the ones who thrive.

The World Economic Forum, in partnership with McKinsey, today revealed 11 new Lighthouses and awarded the designation of "Sustainability Lighthouse" to four existing ones. These manufacturers join a network of 114 manufacturers worldwide that are embracing technology to drive impact.

The power of digitization

The first focus of the network, founded in 2018, was technological adoption: How can you digitize a site to boost productivity while supporting workers and ensuring sustainability?

Lighthouses have been the lead authors of the Fourth Industrial Revolution’s opening chapter—a compelling story full of challenge, excitement, and transformation. They offer around 140 use cases that prove potential and have displayed significant impact. The first foundational chapter of that revolution is now closed, revealing a playbook for successful transformation.

Individually they have applied technologies including AI, advanced analytics, 3D printing and the Internet of Things to support supply network connectivity and improve product development, planning, delivery and customer support. They have shifted gear from piloting to deploying standard use cases while relentless pursuing capability building and an agile approach, typically seen in software development.

But digitizing a single site, while important, is only the first step to transforming the industry. The next challenge is to answer the question: how do you scale from one site to many?

The importance of scaling

In a recent survey by the World Economic Forum and McKinsey & Company in July, two-thirds of respondents cite the scaling of technologies across their production networks as a critical lever to achieve their strategic priorities.

Yet scaling is proving challenging, and companies are progressing slowly. This is especially true for small sites with old equipment and old ways of working. According to the same survey, companies so far have scaled technologies in average to no more than 11% of their production network.

Many Lighthouses, including from new cohort, offer a way forward.

They are deploying large digital transformation programs at scale across 20 to 40 factories in parallel, with thousands of people involved. They have dedicated governance in place to oversee innovative yet standardized technology use cases, over time spans of just 18 to 24 months.

In particular, the most successful Lighthouses practice three crucial must-haves:

- Building a clear strategy: Digital transformation must be designed from customer value back, in close alignment with the company’s overall business strategy.

- Investing in people: Without the right resource and capability models, a transformation will soon run out of resources and steam.

- Setting up the right governance: Without value assurance and governance—and the right execution engine—companies can’t capture the value they seek or generate real impact.

These elements are delivering results. For example, Danone in Opole, Poland, raised efficiency by more than 10% while cutting greenhouse-gas emissions in half. Cipla is deploying advanced technologies in 22 Indian sites in parallel: its lighthouse factory in Indore reduced cost by more than 20 percent and emissions by more than one-quarter. And Flex in Soracaba, Brazil, increased customer satisfaction and employee engagement while reducing material losses by more than three-quarters—and establishing a 4IR-enabled circular economy for electronic waste, enhancing long-term competitiveness.

Manufacturing Lighthouses show that effectively scaling technological solutions not only drives performance but also ensure sustainability and develops people's skills. And when the next shock comes, they will be ready to withstand it.

The Global Lighthouse Network, an initiative of the Forum’s Platform for Shaping the Future of Advanced Manufacturing and Value Chains, is conducted in collaboration with McKinsey & Company. Companies can officially apply to join the Global Lighthouse Network here. Find additional information about the latest Lighthouses here.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Advanced Manufacturing and Supply Chains

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Manufacturing and Value ChainsSee all

Caroline Narich, Maria De Miguel, Jessika E. Trancik and Christine Gschwendtner

November 12, 2025