Opinion

Why PLA is a proven, scalable solution to tackle plastics pollution

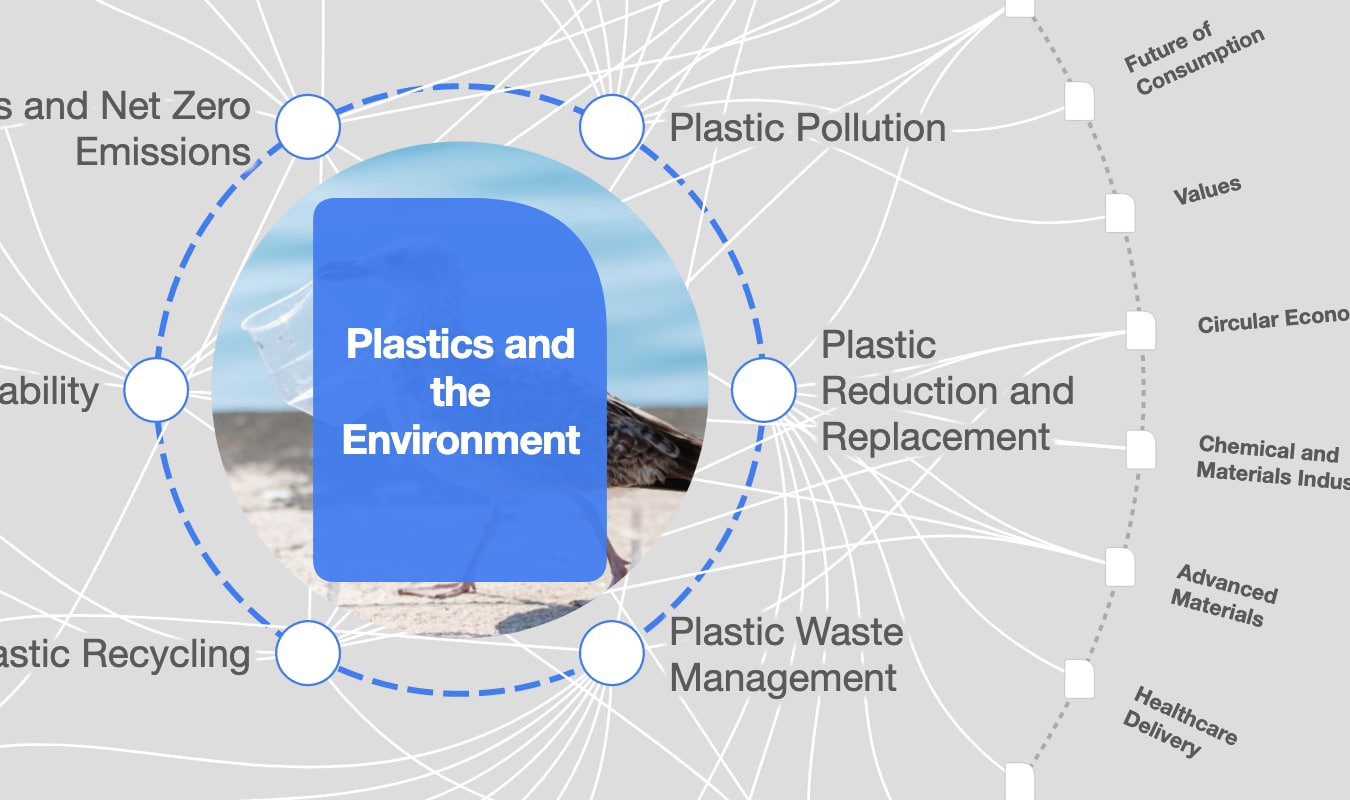

Polylactic acid, or PLA, offers a biobased alternative to conventional plastics. Image: Freepik

- Plastics have transformed modern life by doing everything from reducing waste to enabling medical breakthroughs and making transport safer.

- But the same qualities that make plastics useful – their strength, resistance to degradation and low cost – also create environmental challenges.

- Biobased polymer polylactic acid (PLA) offers an alternative to traditional plastics, that is science backed, cost effective and globally scalable.

Plastics have transformed modern life. From protecting food and reducing waste to enabling medical breakthroughs and making transport safer and more energy-efficient, plastics are embedded in nearly every sector of our economies. Their versatility, durability and light weight have made them indispensable to global trade, health systems and daily convenience.

But the very qualities that make plastics so useful – their strength, resistance to degradation and low cost – also create one of the most pressing environmental challenges of our time. The world produces about 400 million tonnes of plastics each year, and only 9% is recycled. The rest is incinerated, sent to landfill or leaks into nature.

Landfills are a major source of methane emissions – a potent greenhouse gas – while the open burning of plastics is a significant, and often overlooked, contributor to both climate change and air pollution.

The latest United Nations negotiations on a Global Plastics Treaty to end plastic pollution may have collapsed without agreement, but we still need materials, infrastructure and policies that will move us towards a circular economy. To succeed, it must include solutions that are operational today, scalable tomorrow and adaptable across geographies. PLA (polylactic acid) is one of such solutions.

PLA is low carbon, renewable and circular alternative to plastics

Polylactic acid (PLA) is a 100% biobased polymer made from renewable resources like sugarcane and corn.

Biobased materials are derived from plants that absorb carbon dioxide (CO₂) from the atmosphere during growth. This carbon is then embedded and stored in the biobased material, such as PLA.

Newly released scientifically verified life cycle assessment data show virgin PLA has an 85% lower carbon footprint than conventional plastics, has a cradle-to-gate carbon footprint of 0.29 kg CO₂-eq per kg (including biogenic carbon). With 30% recycled content allocation, recycled PLA achieves carbon neutrality (0.00 kg CO₂-eq per kg).

PLA’s greatest strength is its multi-end-of-life (EOL) capability:

- Mechanical recycling when clean, sorted material streams are available

- Chemical recycling via low-energy hydrolysis, restoring food-safe monomers

- Industrial composting for food-contaminated packaging and other items that cannot be mechanically recycled

This versatility means PLA can work in both advanced and emerging waste systems, such as industrial composting.

Industrial composting is the controlled biodegradation of biowaste in dedicated facilities, where temperature (50-60°C), humidity and aeration are carefully maintained. These conditions create an optimal environment for microbial activity (bacteria, fungi, and their enzymes) to break down food waste and compostable polymers, such as PLA, into valuable compost.

The elevated temperatures not only accelerate the biodegradation process, but are also essential to eliminate pathogens from organic waste. Composting facilities are relatively affordable and simple to operate, making them attractive in regions with limited infrastructure. They can also create local jobs, reduce landfill use by diverting food waste, and return nutrients to the soil in the form of compost.

The feedstocks for PLA are globally available. With only 0.013% of global agricultural land currently used for bioplastics production, scaling will not threaten food security.

When examining land use, reducing food waste is crucial. Globally, around one-third of the food produced is never consumed – including losses during supply chains and at the consumer level – and waste accounts for 8% to 10% of global greenhouse gas (GHG) emissions. Reducing food waste would therefore significantly free land for other usage and contribute to GHG emissions reduction.

Why the waste hierarchy matters

The waste hierarchy is clear: landfill is the last resort. PLA enables multiple preferred options above it. In countries without large-scale recycling capacity, composting PLA is far better than landfill or incineration, avoiding methane emissions and returning nutrients to the soil.

This is why compostability should be recognized as a mainstream, credible recycling stream in the global circular economy. Mechanical recycling alone cannot address all waste types, especially contaminated packaging.

Countries like Italy demonstrate the systemic benefits of pairing compostable materials with strong organic recycling: more than 300 composting facilities process organic waste, reducing landfill, producing compost and generating renewable biogas.

The EU’s Packaging and Packaging Waste Regulation (PPWR) requires all packaging to be recyclable by 2030 and recycled at scale by 2035. Within this framework, compostability is acknowledged as a complementary end-of-life option for some dedicated applications, alongside mechanical and chemical recycling.

When talks resume, the Global Plastics Treaty should follow this lead by explicitly including PLA and bioplastics as part of the circular economy toolkit as excluding proven, scalable solutions risks slowing down progress and perpetuating the status quo.

Proven applications across industries

PLA is not experimental. It is already being used at scale in:

- Food and beverage packaging, including compostable coffee capsules and tea bags

- Medical disposables and personal protective equipment

- Personal hygiene products

- 3D printing filaments

- Textiles and durable goods

Many well-known brands are incorporating PLA to meet sustainability goals and respond to growing consumer demand for circular packaging solutions. As of 2024, packaging accounted for 37.14% of the global PLA market, making it the dominant application segment.

Global PLA production is also surging – from an estimated 2.07 million tonnes in 2024 to around 2.59 million tonnes in 2025, with projections showing continued growth towards 6.45 million tonnes by 2030.

One barrier to adoption is inconsistent labelling of biodegradable and compostable materials. The bioplastics industry is actively working with regulators to develop harmonized labelling that reflects PLA’s multi-EOL capability.

At TotalEnergies Corbion, we advocate for two clear labels:

- Mechanically recyclable alongside mainstream polymers

- Industrially compostable

This clarity will help consumers dispose of products correctly, reduce contamination in recycling streams, and increase organics recovery.

PLA offers proven progress, not just promises on plastics

The Global Plastics Treaty remains a once-in-a-generation chance to redefine how materials are designed, produced and recovered. PLA offers a science-backed, cost-effective and globally scalable solution – capable of working within diverse infrastructures, reducing GHG emissions and supporting local economies.

By investing in PLA now, countries can accelerate compliance with emerging regulations, strengthen sustainability leadership and deliver real environmental benefits – today, not decades from now.

If the treaty’s ambition is to be equitable, science-based and future-ready, then PLA must have a seat at the table when it comes to reducing plastics pollution. The world needs proven, scalable options.

While it is disappointing that member nations could not reach unanimous agreement on the treaty text in Geneva, the extreme climate impacts – such as the recent heatwaves in Europe – remind us that we need to act now. As a low-carbon material with sustainable end-of-life pathways, PLA is ready to deliver. The world needs proven, scalable options.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Plastic Pollution

Related topics:

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Circular EconomySee all

Yun B. Choi and Kijune Kim

January 7, 2026