Physical AI can help fix the teetering global supply chain

Physical AI could significantly help our global supply chains, from mining to deliveries. Image: Getty Images/iStockphoto

- Global supply chains are under pressure across their length from mines to roads, due to labour shortages, geopolitics, and the climate.

- Physical AI offers a chance to alleviate some of this pressure.

The global supply chain is one of the most complex manmade systems ever built – a living, shifting network that touches nearly every product, industry and economy on Earth. It’s a remarkable testament to human ingenuity and cooperation.

It’s also threatening to buckle under its own weight.

The COVID-19 pandemic revealed how brittle the global supply chain has become. Since then, geopolitical tensions, climate‑driven disruptions and volatile shipping routes, among other risks, have only further exposed its structural fragility.

As the co-founder and CEO of a company building intelligent infrastructure for autonomous trucks, mining vehicles, agricultural equipment and heavy construction machinery (in addition to 18 of the top 20 automakers), I have a front-row seat to how the next frontier in artificial intelligence will transform industries around the globe. That frontier is physical AI.

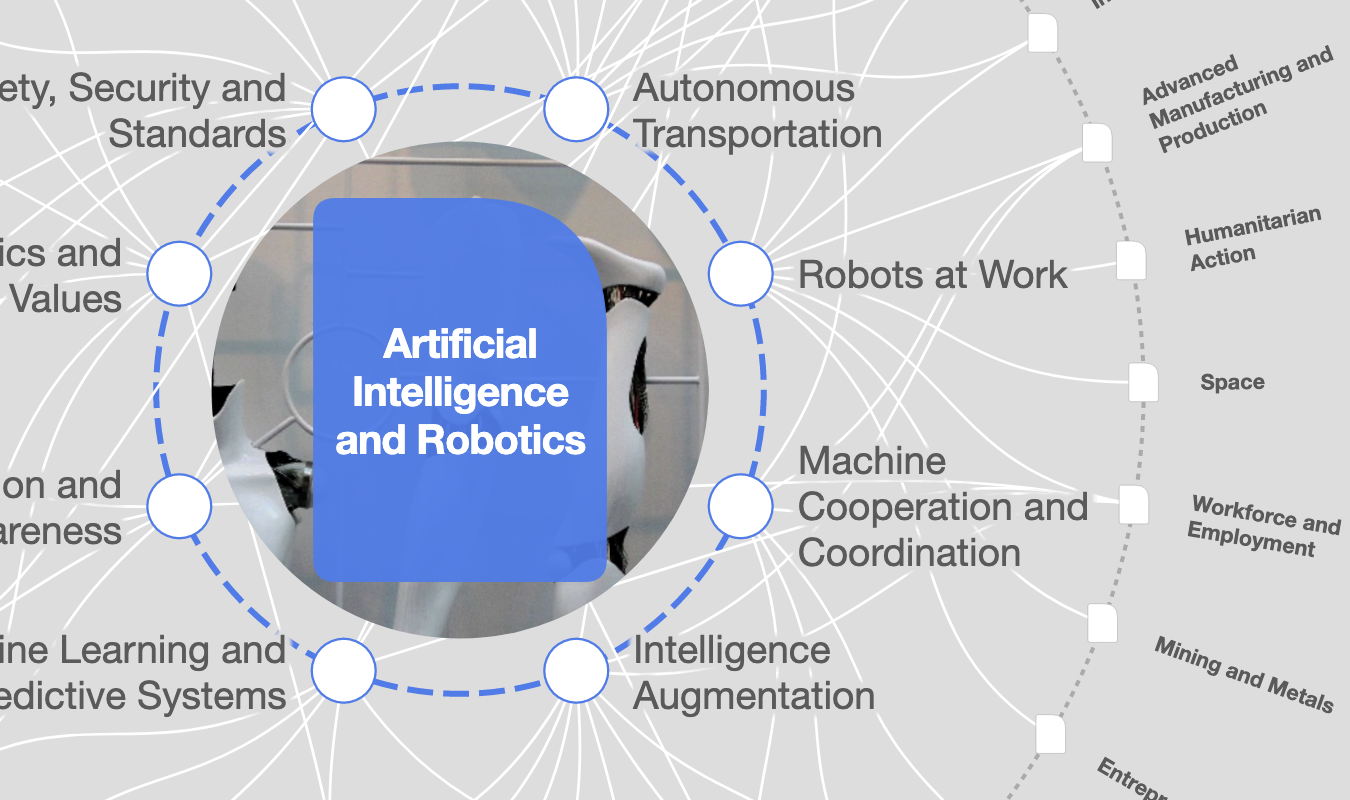

What is physical AI?

Physical AI enables autonomous machines to learn, adapt and perform complex real time operations using advanced sensors, powerful actuators and complex algorithms.

Similar to how large language models power AI on screens, physical AI and its world foundation models – large neural networks trained to simulate and predict the physical world – are enabling machines to perceive, reason and act in the real world.

This fusion of AI with sensor data is the engine behind modern robotics and self-driving cars, as well as autonomous trucks, ships and ports. As the current wave of physical AI matures, data‑driven machines are posed to not only restore resilience to the global supply chain, but to also increase the flow of goods and supercharge the world’s logistic capabilities in profound new ways.

Intelligent trucks keep economies moving

In today’s global supply chain, one of the weak links is trucking. This industry moves massive amounts of goods – $2.2 trillion worth in 2022, expected to reach $3.4 trillion by 2030, according to a recent report. This equates to billions of tons of things moving across roads and bridges – raw materials from mines and farms to factories, and finished goods from ports and warehouses to vendors.

Driver shortages threaten this flow of goods. Currently, there is a shortage of nearly four million truck drivers worldwide, according to the World Road Transport Organisation, and this number doesn’t account for burgeoning freight demands, which are projected to grow by nearly $1 billion by 2032.

The issue of driver shortages has been discussed for years, and autonomous trucking, from driver-assistance technology to full self-driving capabilities, can help solve it. Fully autonomous trucks and haulers never sleep. That means cargo moves continuously – night and day, across geographies. Even Level 2 degrees of autonomy, which include advanced driver assistance systems, can create efficiencies and attract younger drivers. These vehicles can optimize delivery schedules and avoid bottlenecks, resulting in efficiency gains, lower carbon footprints and cheaper shipping costs.

Already we’re seeing this transition to autonomy play out. In 2024, our company, Applied Intuition, partnered with Isuzu Motors Ltd., a Japan-based manufacturer of commercial vehicles, to accelerate their deployment of autonomous trucking solutions.

In Japan, this is a big deal. Recent studies concluded that truck drivers accounted for nearly 35% of overwork-related deaths. In response, the Japanese government capped annual work hours at 3,300 hours. This has raised concerns about driver shortages in an industry already anticipating a 36% decline in drivers by 2030.

Isuzu is now using self-driving trucks on some logistics routes in Japan, with the goal of commercializing Level 4 driving – full autonomy – by 2027. The long-term vision is to unlock round-the-clock operations that can ultimately improve the country’s health and supply chains.

Where else can physical AI help supply chains?

Supply chains, of course, begin well before finished goods are delivered. They start in the earth, where the raw materials are sourced to create the products of modern life. Critical minerals, ores, metals and other materials feed the factories producing electric vehicles, consumer electronics and construction materials. If it’s not grown, it’s mined, and every day the world’s top 40 mining companies pull $2.4 billion worth of raw material from the Earth. Each year 100 billion metric tons of rock, soil and minerals are moved.

This requires a massive amount of work: drilling, blasting, extracting, loading, hauling, processing, separating, transporting and finally distributing the materials to customers. In some cases, stages are controlled by separate companies, and if one segment breaks down the whole process can slow to a crawl. These companies are individually attempting to improve the efficiency of their focus, but the mining supply chain needs to be optimized across the board to create overall resiliency.

In September, Applied partnered with Komatsu, a global leader in mining and construction equipment, to accelerate the development of next-generation intelligent vehicles for the industry. By incorporating autonomy into operations – everything from drills to excavators to haul trucks in mines – companies can ensure a steady stream of raw materials.

This is how physical AI transforms not just mines, but the very foundations of the global economy.

The vastness and interdependence of the global supply chain is both its greatest strength and one of its biggest vulnerabilities.

Given the scale of the global supply chain, the potential gains in efficiency and safety on offer from properly executed and integrated physical AI can yield huge returns. And these returns will only grow as the world welcomes increasing innovations in robotic warehouses, self-driving trucks and ships, and AI-optimized demand forecasting.

I see the future every day at work, and one of the most complex man-made systems is undergoing a massive upgrade courtesy of physical AI – one of the most advanced technologies ever envisioned by humans.

We’ve only just begun.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Artificial Intelligence

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Supply Chains and TransportationSee all

Deborah Dull, Phil Brown and Judith Ketelslegers

March 3, 2026