Physical AI in the supply chain: How its promise can be realized

The foundational infrastructure is developed enough for businesses to apply physical AI. Image: Unsplash/Fachrizal Maulana

- AI embedded into a machine, such as a robot, is physical AI.

- Physical AI can connect to a network of other technologies and data sources, and 'learn' from human training within its physical capabilities.

- With the growing adoption of automated storage and retrieval systems and robotics throughout the supply chain, the foundational infrastructure is developed enough for businesses to apply physical AI.

The global supply chain is running a stress test as we shift into a new era of global development. For decades, the movement of goods relied on a predictable formula: steady demand, abundant labour and stable trade routes. That era is over.

Distribution centres are the heartbeat of the supply chain. To maintain stability against this backdrop, facilities are turning to new kinds of automation: physical AI.

Extreme advances in technology and innovative approaches to modern challenges have created new solutions that were previously inconceivable, but which are now changing the trajectory of what will be seen in warehouses over the next decade.

What do we define as physical AI?

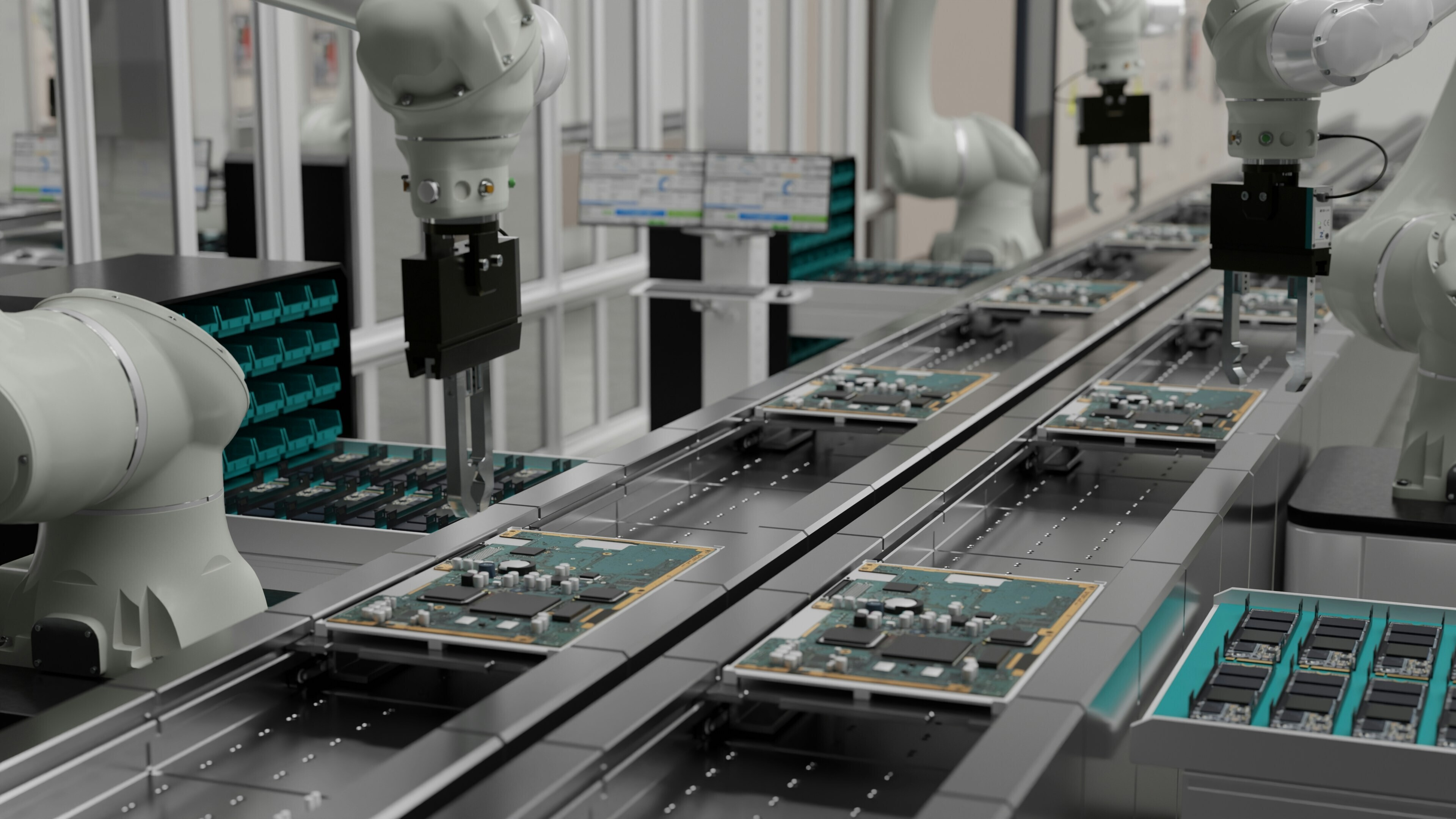

When we think of industrial automation, we often picture 'chain-reaction automation,' conveyor belts with mechanical parts making repetitive motions — fast and precise, but rigid, hard-coded and fragile.

Physical AI introduces a new trajectory: agency. AI embedded into a machine (such as a robot) is physical AI. It gives machinery the ability to perceive its environment and adapt to it using computer vision and sensing, to 'see' a facility as it is — messy, dynamic and imperfect. Complex algorithms pulling from a wide pool of sources allow it to think faster and process greater complexity with a controlled scope.

Physical AI can connect to a network of other technologies and determined data sources, and 'learn' from human training within its physical capabilities. This shift from blind repetition to active perception turns the warehouse from a 'dumb pipe' into an intelligent asset, one that dependably and effectively distributes goods through the supply chain and can provide critical planning insight that humans alone are not capable of.

What is a thinking warehouse?

The true power of physical AI is not in the individual robot; it is in the orchestration. The warehouse of the future will function as a single, cohesive intelligence. This 'thinking warehouse' has a central 'brain' that optimizes the flow of every mechanical asset, from fleets of robotic technologies, to data and insights, to incorporation with the human workforce.

The physical structure of the warehouse will improve alongside physical AI’s growth as more facilities break through the limitations of traditional racking and conveyance.

Distribution centres have a lot to look forward to in the coming decade, including:

- Extended use of real estate: Inventory will increasingly be stored in automated storage and retrieval systems. These are extremely dense, vertical, robot-operated storage structures that allow facilities to store more inventory in their existing footprints. These also allow the physical AI to create a digital twin of every item in the system, providing highly accurate insights into inventory, operations, and patterns, as well as predictive analytics, package-level visibility, and inventory security to prevent loss.

- Holistic optimization and simulation: The system doesn't just react; it plans. The AI runs thousands of simulations to test hypotheses — like, 'What if we move high-velocity items to this zone for the holidays?' It finds efficiency gains that static rules would miss.

- Predictive resilience: Instead of reacting to failures, physical AI predicts them. If goods are in high demand at a particular time of year, if some inventory takes a long time to arrive, or if there is a growing demand downstream that could create an outage, the AI can recognize patterns to help predict when goods should be replenished to prevent an empty shelf.

- A human-centric environment: As the labour shortage persists, workers need to be more productive while avoiding burnout. Future warehouses lean on robotics to give human workers superhuman speed and capabilities, while keeping them safer. Robots will automate tasks that require travel, labour-intensive work, repetition, or are undesirable for the worker. Each worker becomes faster and focused on elevated tasks, while throughput is increased, accuracy is perfected and workers are kept away from workflows that commonly cause injuries.

- Network collaboration: Intelligence radiates outward from the distribution centre into the supply chain. The warehouse can communicate upstream, signalling suppliers to correct recurring packaging defects and notifying them to prepare for upcoming needs. Downstream, it minimizes the labour of the next person in the chain by 'compiling' perfectly sequenced pallets that match the specific aisle layout of a destination store and the order in which the delivery is needed.

The reality check: Navigating the transition

We cannot pause the global economy to rebuild its infrastructure from scratch.

Most warehouses have limited space and ongoing operations. Automated storage and retrieval systems solutions are commonly modular and can be installed in phases around ongoing operations. This phased approach allows the workforce and operations to adjust over time, improving acceptance and avoiding a sudden disruption to revenue. It also breaks up capital expenses over time, which could be offset by efficiency gains and by the costs saved from avoiding new construction.

Governance is also a challenge. As these systems gain the agency to orchestrate billions of dollars in goods, the central question becomes: how do we ensure they remain steerable, transparent and aligned with human intent? The complexity of such a system can easily exceed the ability of any single human to fully comprehend its state in real-time.

To solve this, a framework of graduated agency is applied, a 'trust ramp' that moves from analysis to insights to recommendations to supervised autonomy. This ensures that, as we grant these systems larger decision-making powers, they remain proven, fair and accountable.

Why the convergence now?

This vision is no longer science fiction.

With the growing adoption of automated storage and retrieval systems and robotics throughout the supply chain, the foundational infrastructure is now developed enough for businesses to apply physical AI.

Software now has powerful reasoning models with strong multimodal capabilities. Understanding data from thousands of streams is now possible. In the next few years, we will see a convergence of abilities with state-of-the-art systems that can reason across this very wide context, enabling new levels of reasoning, prediction and adaptive decision-making.

Physical infrastructure projects take years to complete. The AI capabilities of 2028 will dwarf those of 2025. Leaders must design facilities today that are 'hardware-ready' for the software brains of tomorrow.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Artificial Intelligence

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Supply Chains and TransportationSee all

Deborah Dull, Phil Brown and Judith Ketelslegers

March 3, 2026