Why mushroom mycelium could be your next house, handbag, or ‘hamburger’

Mushroom Mycelium based products could prove key to creating a circular economy. Image: Unsplash/Jesse Dodds

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

Climate Crisis

- Mycelium is the mass of branched fibers comprising the vegetative part of a fungus.

- The substance can be used to grow strong and compostable material in different shapes.

- It can make everything from building bricks to meat alternatives.

- Mushroom mycelium could prove key in the creation of a circular economy.

Easy to grow and fully biodegradable, mycelium – essentially, the vegetative part of a mushroom – could prove to be the ultimate green material for the future. It can be turned into everything from fashionable handbags, to packaging, to even bricks.

What is Mycelium? Understanding mushroom mycelium.

Mycelium is the mass of branched fibers making up a fungus. It is a safe, strong, and biodegradable material with a wide range of uses. However, unlike plastics and other synthetic materials – which can take hundreds of years to decompose – mycelium-based products naturally degrade after their intended product cycle.

More sustainable, these products could also help create a circular economy, which aims to eliminate waste and transform how we produce and use goods. It is estimated that the circular economy could offer up to $4.5 trillion in global economic benefits by 2030, alongside environmental benefits such as lower emissions and better land use.

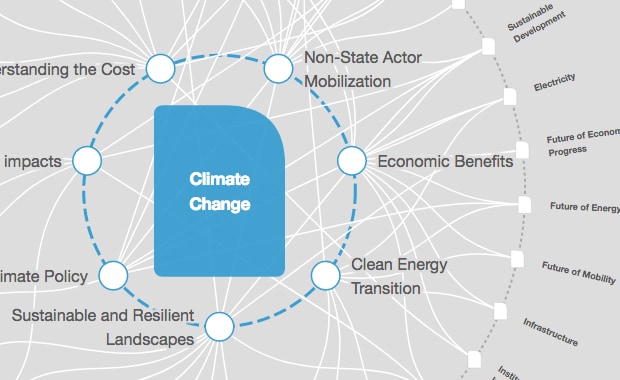

What is the World Economic Forum doing about the circular economy?

To help support circular innovation, the World Economic Forum has created the Scale360° Playbook, an initiative developed to build lasting ecosystems for the circular economy, bringing together technologists, researchers, entrepreneurs, and governments to help maximize resources and expertise. Additionally, emerging innovators from around the world can connect and work together in sharing ideas and solutions through UpLink, the Forum's open innovation platform.

Here are five sustainable alternatives that can be made with mycelium.

1. Greener building materials

Mycelium composites – made by growing mycelium on agricultural waste – can create low-cost and greener building materials, which could help reduce reliance on fossil fuel-based products in the construction industry.

Mushroom mycelium based bricks created by Ecovative Design made the headlines in 2014 when they were used in an award-winning compostable tower at New York’s Museum of Modern Art.

Meanwhile, Redhouse Architecture says it can recycle derelict homes by demolishing buildings and mixing the remains with mycelium to create new material – a process which could also create temporary homes in disaster zones using a portable ‘biocycler’.

2. Sustainable clothing

Clothing manufacturers are increasingly turning to mycelium to create green alternatives to leather and synthetic textiles. These could prove vital in reducing the carbon footprint of the fashion industry, one of the world’s most polluting sectors.

Examples include MycoWorks’ leather alternative, Reishi, which was unveiled at New York Fashion Week and hailed by Vogue as “nothing short of revelatory”. Meanwhile, Bolt Threads has signed a deal with global fashion houses including Adidas and Stella McCartney to use its mycelium-based textile Mylo in products like footwear, clothing, and accessories.

3. Compostable packaging

Mycelium can be used to make standard and custom-molded packaging that is 100% biodegradable, thereby reducing reliance on plastic and polystyrene. Mushroom Packaging uses hemp hurds and mushroom mycelium to create water-resistant and insulating solutions that compost within 30 days when added to soil.

Swedish furniture giant IKEA and computer manufacturer Dell are some of the biggest businesses to have already committed to using mycelium packaging, with smaller firms such as UK-based non-alcoholic spirit maker Seedlip also joining the trend.

What is the World Economic Forum doing about plastic pollution?

4. Animal-free meats

Mycelium can also be used to make plant-based ‘meats’. Unlike other meat alternatives which predominantly come in ground form – such as burgers or mince – mycelium can be grown into a 3D form or shaped post-processing.

Meati, a Colorado-based alt-meat brand, claims its mycelium-based products will eventually use 99% less water and land and emit 99% less carbon than industrially-produced animal meat.

5. Disposable healthcare products

In a bid to address disposable plastics in the beauty industry, Ecovative Design has created MycoFlex foam, which the company says is 100% compostable. The foam can be used in anything from make-up sponges to single-use slippers and masks.

As for the future, the company thinks mycelium will be capable of creating medical products – even organs. “My dream is to one day grow a lung and seed it with lung cells and use the mushroom mycelium to create the capillary network and use the human cells to create the actual lung,” CEO Eben Bayer told CNN.

If this sounds a stretch, Tradd Cotter, microbiologist and owner of research company, Mushroom Mountain, sounded a similarly optimistic note in National Geographic: “As far as [mushrooms’] versatility in agriculture, medicine, and in the laboratory, there’s not much they can’t do.”

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Climate CrisisSee all

Mette Asmussen and Takahiro Furusaki

April 18, 2024

Laia Barbarà and Ameya Hadap

April 17, 2024

John Letzing

April 17, 2024

William Austin

April 17, 2024

Rebecca Geldard

April 17, 2024