How small, strategic steps can pave a practical path to greener manufacturing

Small and mid-sized businesses in industries like manufacturing need to build a green compliance strategy that doesn't create an administrative burden. Image: iStock/danchooalex

- Businesses are under increasing pressure to gather environmental compliance data and show a commitment to sustainability.

- Green compliance can help to lower emissions, as well as reducing risk and building business continuity.

- For small and mid-sized firms, a six-step strategy can help to ensure green compliance doesn't turn into an administrative burden.

Across global value chains, organizations are under growing pressure from customers, investors and regulators to provide environmental compliance data and demonstrate concrete sustainability commitments. Emissions reporting, responsible sourcing and credible targets are becoming part of procurement decisions.

For many smaller and mid-sized firms, this collides with day-to-day constraints, as well as limited time, specialist capability and headroom for investment without a clear payback. For these businesses, the World Economic Forum report Sustainability Meets Growth: A Roadmap for SMEs and Mid-Sized Manufacturers mirrors how operational change really happens – through a staged progress, early wins, simple measurement and then scaling.

Smaller and mid-sized companies need a simple, repeatable loop that can cut costs, reduce emissions and strengthen resilience, without turning sustainability into an administrative burden.

Making green compliance more robust

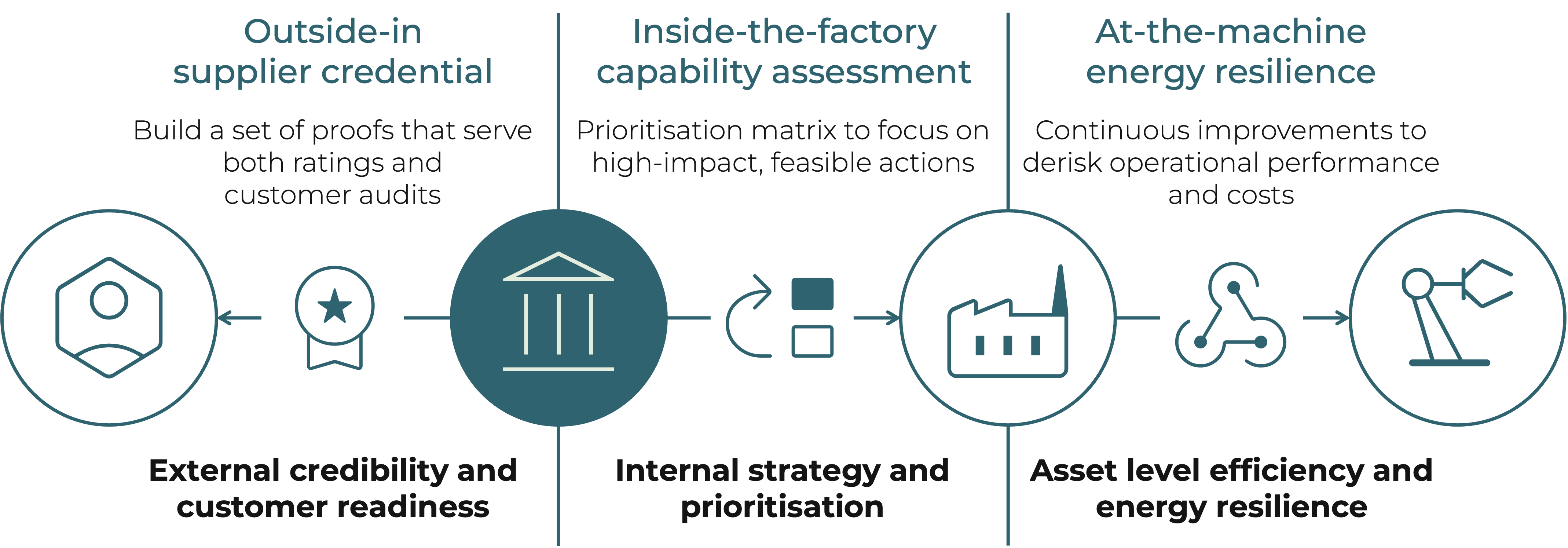

Most organizations need to satisfy customers, set priorities and improve day to day operations at the same time. To do so while also fully satisfying compliance needs, they should focus on:

- External credibility and customer readiness. Build reusable evidence, policies, baselines, actions and proofs, so customer requests do not become a scramble. Some organizations use structured supplier assessments, such as EcoVadis, to support this.

- Internal strategy and prioritization. Decide what to do first based on return and practicality. Capability frameworks, such as CoSIRI, can help identify high-impact gaps and sequence improvements.

- Asset-level efficiency and energy resilience. Track energy, waste and emissions at a manufacturing site or process level, then translate the results into cost savings and avoided emissions. Approaches such as a Reliability Asset Management Programme (RAMP) can support this, but the principle is universal: use a small set of signals to find losses early and act before they become a disruption.

Six steps to green compliance

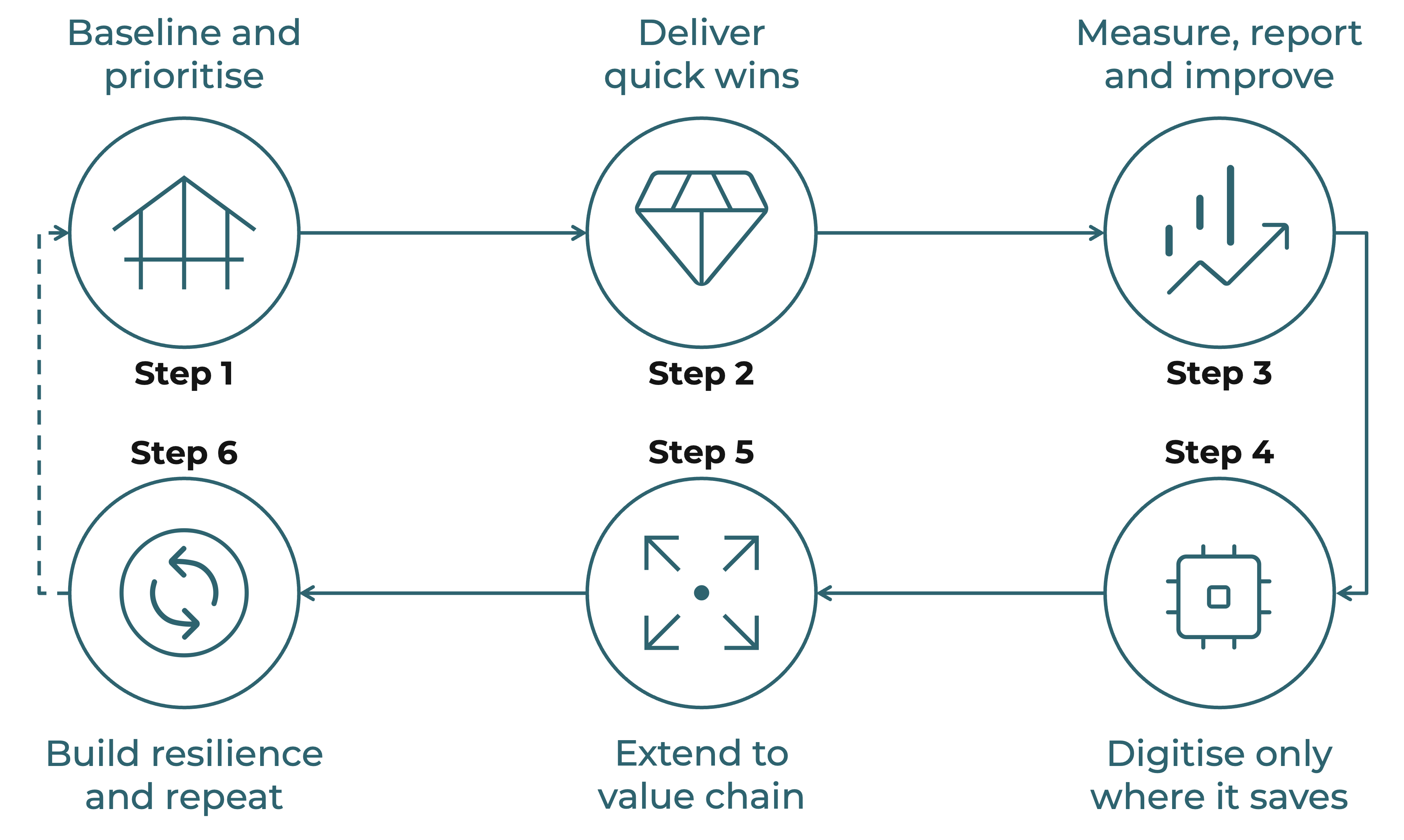

With the above strategies in place, the following six steps will form a loop to build up your green compliance processes over time. By starting small and proving value, you can then repeat the steps with better data and sharper priorities.

Step 1: Baseline and prioritize

Establish a simple baseline for direct emissions and purchased energy, often referred to as Scope 1 and Scope 2 emissions. For most firms, bills and meter readings are enough to begin this process. Alongside this, list your biggest suppliers by spend so you are ready for future supply chain requests.

Keep the plan light. Choose one focus area, set two measurable targets and run a short weekly review to unblock decisions. Start building your evidence from day one and use a capability check to keep priorities realistic.

Step 2: Deliver quick wins that improve profit

Start with high return, low complexity projects to create early wins and develop knowledge. Keep examples widely applicable. Improve energy efficiency through better lighting and basic controls, for example, or cut energy waste with simple controls and better discipline around how manufacturing processes start up and shut down.

Involve the workforce through short training and improvement sessions because practical ideas often come from the people closest to the work.

The aim is not to build a long list, it’s to prove value quickly and create capacity for the next wave of changes.

Step 3: Measure, report and improve

You don’t need a complex software platform to start building a green compliance strategy. Use simple dashboards for energy, waste and emissions, and review them regularly. Share a short monthly update internally and a simple quarterly update for key customers, as needed.

Translate improvements into business language, cost savings, avoided waste, improved stability and reduced risk of non-compliance. And keep the evidence current so you can respond consistently rather than reinventing the answers.

Step 4: Digitize where it saves time and cash

Digital tools are most valuable when they reduce manual work and improve decisions. Start where the return is clear with basic monitoring, simple alerts and easy logging to improve visibility and accountability.

Use digital tools to make the same data serve multiple purposes, such as operational performance, emissions tracking and customer reporting.

Step 5: Extend into products and supply chains

Embed sustainability into product and process decisions and redefine procurement criteria to reduce emissions and build resilience. A practical starting point is to apply one simple rule to design or process changes, for example, a manufacturer could consider reducing material mix, cutting unnecessary specification or improving reuse and repair.

In the supply chain, begin with your most significant suppliers. Ask for basic information on energy sources and improvement activity and share simple templates so smaller partners can respond. This creates momentum without demanding perfection.

Step 6: Build resilience as a habit and then reset the baseline

The goal is repeatable capability. Use what you have learned to refresh the baseline, tighten targets and select the next set of actions.

This is where energy and operational signals can become an early warning system. If you can see patterns of loss or drift, you can act earlier, protect performance and reduce the likelihood of disruptive events.

The result should be a programme that improves both sustainability outcomes and operational resilience.

Scaling sustainability

This approach protects margins, defends revenue and builds credibility with customers and investors without turning sustainability into an administrative burden. It sets foundations, delivering quick wins that can be scaled into longer-term planning and communication on green compliance.

Lower emissions and disciplined operations also mean lower risk and stronger business continuity. When each improvement cycle is built on verified data, sustainability becomes a financial asset, not a cost centre.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Small and Medium-Sized Enterprises

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Manufacturing and Value ChainsSee all

Stefan Reuther

February 10, 2026