Why the circular economy must link up the whole supply chain

Maersk, whose flagship MV Maersk Mc-Kinney Moller is pictured, has begun creating ‘digital twins’ of its latest container ships to assess the use of the materials involved. Image: REUTERS/Renata Dabrowska/Agencja Gazeta

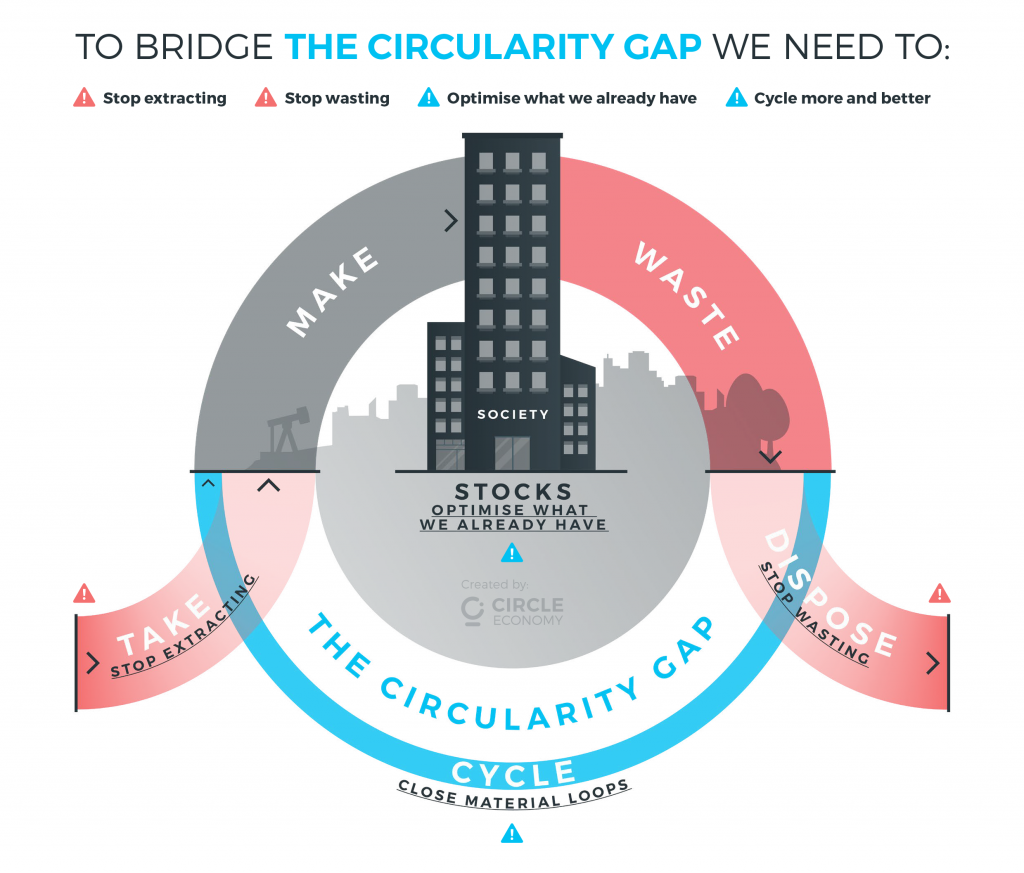

Finally, the long-discussed concept of the circular economy (CE) seems ready for takeoff. More and more observers see new information technologies like the internet of things (IoT), big data analytics or blockchain as the powerful means everybody is waiting for.

And yes, its promises are truly thrilling. Yet the real door-opener is still to be found in the analog world: It’s about trustful collaboration. Doesn´t sound too sexy, does it? We know. But only when all actors along the product life cycle find profitable ways to take resource scarcity into account, and only if they share both costs and benefits, will CE be able to unfold its full potential.

So trustful collaboration is asking for a lot. It needs to convince decision-makers of the business opportunities they get once they trade their silo-oriented optimization rationale for a holistic-management approach that addresses the entire life cycle of the products and the materials involved.

Sure, the road is still long. While not yet being comprehensive enough, the first brilliant examples of circular approaches show the way forward. And it is not only about consumer market visionaries like Ray Anderson of Interface, or Yvon Chouinard of Patagonia. Making use of circular economy to prosper and differentiate products and services is suitable for business-to-business heavyweights, too. For example, ocean carrier Maersk created a digital twin of their latest container ships down to the smallest bolt. Through this, the company will ultimately know how much and what material is being used in their fleet. During routine overhauls or at the final disassembly, Maersk has a clear systemic view on which parts and materials can be reused, remanufactured, upcycled or continue to stay in the circular flow of shipbuilding. This is similar to Caterpillar, whose remanufacturing business takes back more than 150 million pounds of material from customers per year. According to a survey by The Conference Board, Caterpillar’s portfolio of sustainable products and services generates almost one-fifth of company’s total sales and revenues.

It's not by chance that most CE case studies are when economically strong asset owners and service providers such as Caterpillar and Maersk are in the driving seat. The same applies to powerful vendors, for instance tech giants such as HP and Dell who have established highly efficient return systems for used products. Why is it that CE pioneers are often found among these kind of companies? The two most obvious reasons: on one hand, these players have understood the value of the materials involved to such an extent that they decided to take on responsibility for them. On the other, they have the business acumen to guide and influence the use phase of a product.

Albeit, all of these cases studies are rather short value chains. CE examples covering entire chains are still yet to be found, which is no surprise at all – implementing comprehensive cradle-to-cradle scenarios is one of the biggest challenges facing supply chain managers. The degree of difficulty can be seen in the chemicals industry. Here a lot of companies have already gained deep expertise in extending the reach of sustainability management to the production level; for example, the “Production Verbund” of BASF, a role model for efficient and inter-connected material and energy flow in chemical production. However, compared to big asset owners, service providers or responsible vendors, the power of the process industry to convince value chain partners to participate joint CE strategies is much more limited. Chemical companies work upstream as a tier-one value creator after the extractive industries. Since most partners are downstream, laying out a CE scenario is like pushing a rope.

However, both downstream and upstream, the headwind in favour of CE is blowing strong. Still, most companies optimize their operations and products within their own narrow sphere of influence. Even the current most progressive perspectives towards sustainability are not yet broad enough. In his recent blog on MIT Sloan, Toronto-based professor Cory Searcy explains why: “Corporate sustainability is often framed using the triple bottom line (TBL) of economic, environmental and social performance. But the TBL does not connect company performance to the economic, environmental, and social resources on which they rely. Performance is assessed relative to the company itself or its peers, rather than against thresholds linked to those resources. This makes it impossible to assess true sustainability.”

To overcome this deficiency, Searcy calls for an embedded view that makes explicit connections between a company’s performance and its place in society, which itself exists within the natural environment. With this in mind, sustainable businesses must operate within economic, environmental, and social thresholds. To make this concept work, reference thresholds and targets, such as the planetary boundaries and the Sustainable Development Goals (SDGs), need to be translated into tangible business actions. The Science Based Targets initiative illustrates how this can be done, by focusing on greenhouse gas emissions. Another example is the UN Global Compact’s CEO Water Mandate, which advances water stewardship and sanitation.

So what does this all mean with regards to CE? First of all, every constituent of a specific value chain needs to understand that the chain as a whole will lose, once an indispensable resource is gone. This can be in its own production, or in someone else´s. Thus the chain, too, must take into account the planetary limitations. Like each and every one of its constituents, the supply chain needs to operate within economic, environmental and social thresholds. Supply chain managers have to develop metrics that take the sustainability context into account, as well as building relationships with players across the entire chain.

The concept only works if supply chain partners build up mutual trust in the sustainability information each partner is giving. Therefore, CE requires transparency about associated materials and financial flows of the product and its components during their entire life cycles. A bold example of this thinking was the environmental profit and loss analysis Puma published already in 2011.

The required transparency can easily be provided by the newest information technology of connected devices, big data analysis, cloud computing, or distributed ledger technology (aka blockchain). Coupled with IoT tracking and AI-enabled global data matching models, these are necessary ingredients to bridge the physical gap along individual processes in supply chains during a product’s use phase and at end-of-life.

Russian startup INS provides a disruptive example of what is possible with its platform connecting grocery manufacturers and consumers. One of the key benefits will be to minimize food waste caused by the deficiencies of push-oriented retail systems.

The crucial IT foundation is in place. Most companies run modern enterprise resource-planning systems to synchronize material and financial flows. This enables and supports decision-making and optimization within an individual organization. The information is available, but the dots need still to be connected. Supply chain managers need to extend the focus of data analysis to the whole value chain. Only then they will get the right information to help both themselves and their supply chain partners harvesting the multiple benefits of a CE.

The business cases of a circular life cycle are dependent on finite resources and must consider all value creation from the production, use, end-of-use to the recycling phase. Recent developments to transform business models from selling products to providing services offer the opportunity to establish circular models, as shown by Interface, Maersk or Caterpillar. In any case, a wider understanding and ownership of the life cycle of a product is required.

Here, advanced management education comes into play. Innovative holistic education curricula will provide the required intellectual ingenuity, creativity and mindset to transform organizations towards sustainable and long-term viable businesses. Without considering the bigger picture of the planetary boundaries, all constituents of individual or specific value chains will lose in the end once a resource is gone. Information technology can create the required transparency on flows and availability of materials and the associated financial costs. This elevated transparency will become the foundation of fact-based trust – making CE the most profitable business model of the 21st century.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Circular Economy

Related topics:

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Circular EconomySee all

Felipe Basso

November 13, 2025