How will manufacturing keep up with the technology curve? A new approach

The manufacturing industry must adapt to survive Image: Photo by Homa Appliances on Unsplash

- Today’s manufacturing landscape faces unprecedented challenges and industry is struggling to keep pace with modern demands.

- A new, systematic approach is needed, integrating operational excellence with digital tools and sustainable principles to elevate manufacturers to world-class excellence.

- The World Economic Forum, in collaboration with NEOM and industry partners, is co-developing the next-gen operating system — a replicable framework to guide manufacturers towards scalable, responsible transformation.

The manufacturing sector faces unprecedented challenges, many of which have intensified over the past three to four years. The strain on global supply chains, exacerbated by events, such as the geopolitical tensions in the Middle East and Europe, has led to a significant shift, with 92% of companies now regionalizing their manufacturing footprints. The need for sustainability is unquestioned, 90% of executives believe it's very important, but only 60% have sustainability strategies in place and only 25% have sustainability incorporated into their business model. Simultaneously, emerging technologies, like generative AI, are seen as game-changers — 80% of executives believe AI will boost productivity and 95% say it will enhance creativity. However, 84% of executives report struggles in training existing talent on new technologies, revealing that workforce development remains a major hurdle.

The ideas and foundations for 4IR technologies have been developing for over a decade, yet only a fraction of companies, such as the factories within the World Economic Forum's Global Lighthouse Network, are extracting significant value from them. What holds others back? A key issue seems to be the lack of proven, replicable pathways to success. It’s time to study what makes successful companies thrive — identifying the key drivers behind their achievements — and use those insights to create a systematic, repeatable approach that others can adopt.

Most current manufacturing systems are still strongly anchored in 'lean'

Today, most production systems are still built on variations of the Toyota Production System (later codified as the 'lean production system'), developed over 70 years ago – and only around 30 years after Ford’s invention of the continuous production line. Lean and other operational excellence frameworks provide a solid foundation for continuous improvement and workforce upskilling, but they have natural limits in flexibility and adaptability within the narrow confines of standardized procedures and product specifications. Also, most operational excellence frameworks are strongly focused on cost reduction in production, neglecting value potentials in non-manufacturing areas. This contrasts sharply with the need for agility in today’s fast-changing markets. Digital technologies provide the opportunity to enhance the proven operational excellence approaches to create a more agile, robust and sustainable setup.

How is the World Economic Forum contributing to build resilient supply chains?

Learnings from the Global Lighthouse Network

To see what works, we can look at companies that have managed to extract value from the transformation of their operations. Looking at these front-runners shows that investing in sound foundations of digital technology and integrating sustainability and people at the centre of the transformation leads to benefits that go beyond pure bottom-line impact, e.g. a more engaged workforce and positive impact on the environment.

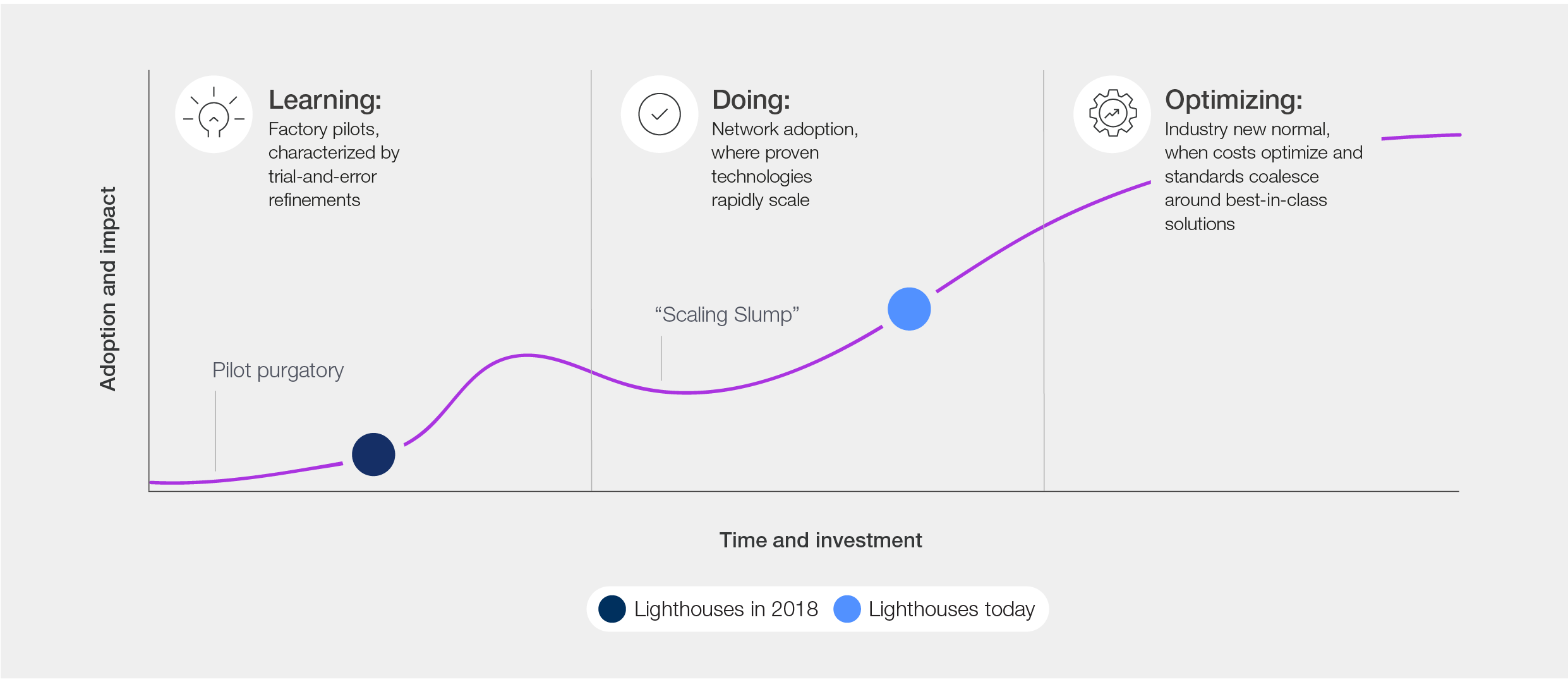

Unfortunately, companies just starting on this journey often end up in pilot purgatory, where individual use cases are successful, but not scalable and not connected to business goals. Continuing on the transformation journey, they reach the so-called 'scaling slump' - 88% of executives admit to struggling with capturing value from these investments when trying to scale them across their entire network.

By contrast, 75% of companies within the World Economic Forum Global Lighthouse Network are now able to roll out new advanced use cases within six months, showing that they mastered scaling and rolling out improvements across their network.

What if we could integrate the learnings of lighthouses into a repeatable approach that others can follow with less trial and error? What if we could codify this into a system, similar to how the Toyota Production System was codified seven decades ago?

The next-generation industrial operating system: Driving responsible transformation

The World Economic Forum, in collaboration with NEOM and industry partners, has started an initiative that aims to create the next-generation operating system, driving responsible transformation. This initiative aims to codify learnings from leading industrial players to guide other companies on their transformation journey in operational excellence, digitalization and sustainability.

The initiative is led by industry partners, all recognized as innovators and thought leaders in their field, setting the benchmark for digitally-enabled operational excellence. These partners include Bain & Company, Bosch, Engro Corp, ETH Zurich, Foxconn Industrial Internet, Johnson & Johnson, Koç Holding A.S., Siemens Advanta, Tata Steel and Tulip Interfaces. Together, they bring their expertise to co-create cutting-edge solutions.

NEOM contributes foundational research to the initiative, drawing from its own 'Advanced and Clean Manufacturing System.' This system was developed to support industrial transformation in Oxagon – the reimagined industrial city of NEOM – and piloted in the Kingdom of Saudi Arabia.

This industrial operating system aims to go beyond theory, to be designed as a simple, practical and intuitive tool to assess a company’s operational maturity and guide its transformation journey. It will help manufacturers move systematically towards world-class performance in a self-guided way, which can be consistently replicated across their entire network.

What’s next: A call to collaborate

The first insights of this industrial operating system framework are set to be published in Q1 2025 – a first glance is in the picture below. This will mark the beginning of a broader effort to pilot, refine and implement the system across various sectors and regions.

This framework is not meant to become just a toolkit, but a means to establish a global standard for efficient, digital and sustainable operations. It integrates learnings from industry leaders to help others overcome the challenges of the digital age, enabling them to achieve a higher level of excellence. A systematic, integrated approach is essential to navigate this complexity and drive true, scalable change.

If you are interested in contributing to or collaborating on this ambitious initiative, we invite you to reach out to the Next Generation Operating System team

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Stay up to date:

Fourth Industrial Revolution

Forum Stories newsletter

Bringing you weekly curated insights and analysis on the global issues that matter.

More on Manufacturing and Value ChainsSee all

Eisaku Ito

December 18, 2025