It’s time for India’s creative workers to go global

Crafting the future: India has 60% of the global workforce in informal creative manufacturing Image: REUTERS/Fayaz Kabli

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

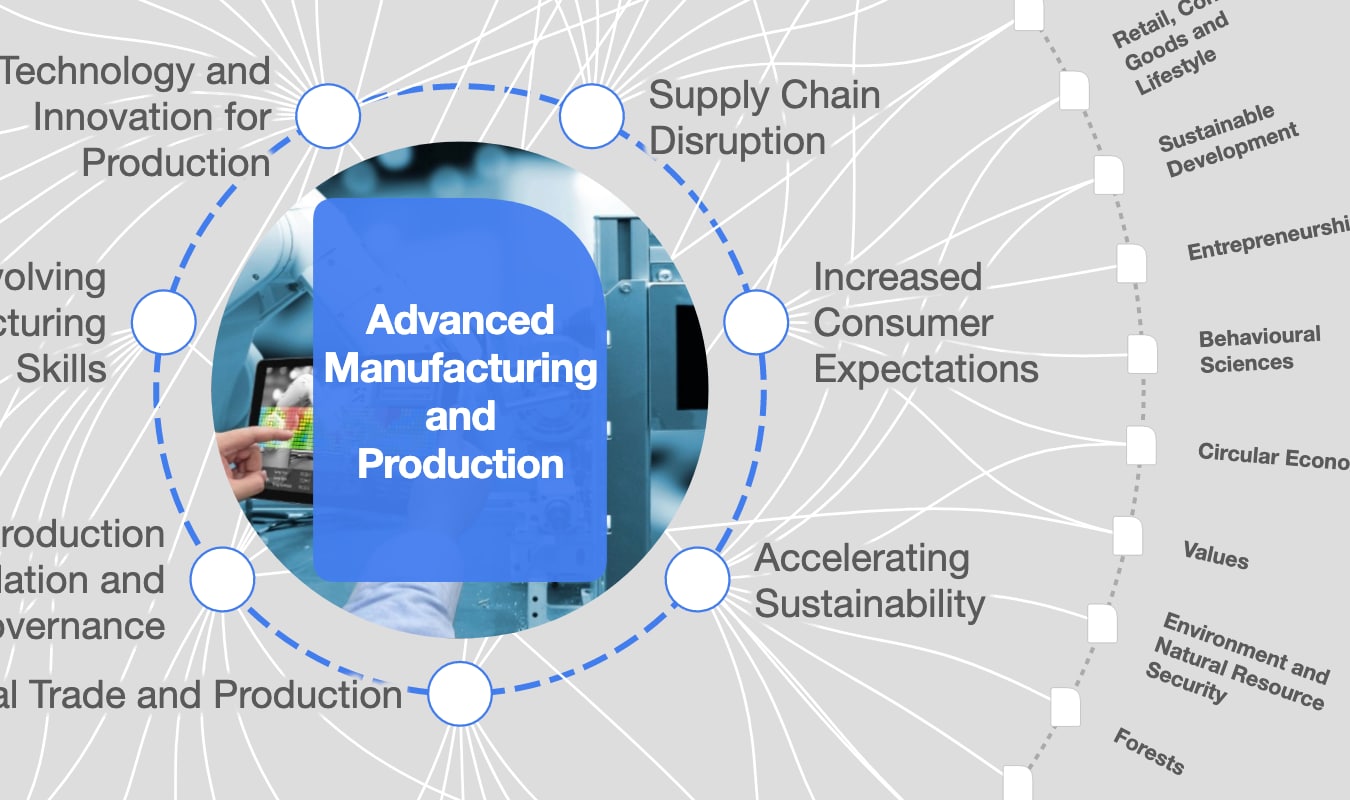

Advanced Manufacturing

More than a century of manufacturing growth has been led by a move towards centralized mass production and increasing mechanization.

This has delivered efficiency and consistency, but often at the cost of meaningful work, fair wages for laborers and large externalities such as poor environmental impacts. Traditional, localized and often labor intensive manufacturing, collectively termed as creative or artisanal industries, have typically been relegated to exotic and niche status.

This underestimates the importance of the artisanal industry sector as a key source of viable and long-term livelihoods for more than 40 million people across India, even as we seek to join the league of advanced industrialized economies in the world.

India wants to increase the share of manufacturing livelihoods from 16% of GDP to 25% in the next 10 years. Meanwhile, high-end manufacturing is transitioning to fewer jobs on the shop floor. The majority of jobs in manufacturing will be created by industries where human-powered, intensive manufacturing is both necessary and seen as an asset. This points to creative sectors such as fashion and lifestyle products, with a quick turnover of design, as a major source of manufacturing jobs in the future.

Age-old creativity, modern manufacturing

India has the widest variety of hand skills and intellectual property, along with 60% of the global workforce in the informal sector of creative manufacturing, which spans materials such as textiles, wood, metal, ceramics and natural fibers. Not only is this a great resource for low-carbon- footprint production, but a great employment generator. There are reasons why India still holds just 2% of global market share in this space. The lack of organized and compliant supply chains with the ability to supply at scale is key. Larger corporate players who are concerned with ethical buying are unable to engage with the scattered, largely rural skill base.

The fear of labor management has further stunted growth in the sector. There is a pressing need to view this sector from a different lens. This sector requires significant creative input and quick turnaround in design, within a relatively low cost, fixed framework of investment and production infrastructure, with a significant contribution of handwork. The creativity is embedded in stories and techniques that are age-old, but once in the hands of modern designers, can be transformed into products with great depth and vision for the discerning customer. A case in point is the intricate double Ikat, tie and die fabrics hand-woven by thousands of weavers in southern, central and eastern India. Crafted with natural dyes, the weft and warp yarns are independently tied and dyed, but when woven together they magically reveal the most intricate motifs.

As we discuss the Sustainable Development Goals we see that across Asia, Africa and Latin America, indigenous populations can cater to modern consumption economies, out of their village production centers, using the best of modern technology and digital solutions. Globally compliant supply chains can be designed that are decentralized, as has been done in India.

Built on the backbone of financial inclusion, groups of micro entrepreneur women can be aggregated into their own businesses, that are professionally managed and can reach scale. Banks lend to these businesses at lower rates of interest than micro-finance institutions, since collectivization and improved management mitigates risk. Partnerships with ethical buyers leads to sustainable business, reducing migration from rural areas, improving gender parity and alleviating poverty, which are all part of the SDGs. Harnessing the creative power of India’s manufacturers will help us build a more resilient society for the future.

Author: Neelam Chhiber is Managing Director at Industree and a Schwab Foundation Social Entrepreneur. She is participating in the World Economic Forum’s Annual Meeting in Davos.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Advanced ManufacturingSee all

Stephanie Wright, Memia Fendri and Kyle Winters

February 13, 2024

Maya Ben Dror and Lena McKnight

January 31, 2024

Dr. Matthew Putman

January 17, 2024

Kyriakos Triantafyllidis and Andreas Hauser

January 16, 2024